A staggering 79% of companies with high-performing supply chains, often involving multiple suppliers and a robust business network, achieve revenue growth greater than the average within their industries, securing a competitive edge and significant savings. This highlights the critical role that effective supply chain network optimization strategies, including inventory visibility and multiple suppliers, play in giving a business a competitive edge and preventing excess inventory, thereby contributing to its success. By streamlining operations, enhancing efficiency, and optimizing supply chain networks, these strategies can lead to significant benefits for the business network, including reduced costs, improved customer satisfaction, and a more efficient supply network. In today’s fast-paced market, understanding how to leverage these tactics is not just advantageous—it’s essential for staying competitive. Short and simple: optimizing your supply chain network isn’t just a good idea; it’s a cornerstone of thriving in the modern business landscape.

Key Takeaways

- Recognizing the importance of optimization is vital for a resilient supply chain, ensuring efficiency and cost-effectiveness in your operations.

- Implementing strategies like route analysis and inventory management can significantly enhance the performance of your supply chain network.

- Leveraging technological advancements, such as AI and machine learning, can automate processes in supply chain network optimization and provide predictive analytics for better decision-making.

- Adopting centralized management provides a clearer overview of the supply chain, facilitating improved coordination, communication across various departments, and network optimization.

- A multichannel approach allows for flexibility and responsiveness to consumer demands, which is increasingly important in a dynamic market environment.

- Diversifying supplier networks helps mitigate risks and ensures continuity in the face of disruptions, making your supply chain more robust.

- Addressing challenges head-on with strategic planning and regular assessments can lead to continuous improvement and long-term success in supply chain optimization.

- Regularly measuring outcomes against set benchmarks is crucial to understand the effectiveness of your optimization strategies and identify areas for further improvement.

Understanding Optimization Importance

Competitive Edge

Supply chain optimization is crucial for staying ahead in today’s fast-paced market. Companies that fine-tune their supply chains, through network optimization, can react swiftly to new opportunities and challenges. They leverage data analytics for supply chain network optimization to forecast demand, manage inventory, and streamline operations. This agility leads to a stronger market position.

Efficient supply chains also contribute to sustainable practices. By reducing waste and improving resource management, businesses not only cut costs but also appeal to environmentally conscious consumers. This dual benefit reinforces a company’s reputation and competitive advantage.

Cost Efficiency

Optimization directly slashes operational costs. By identifying bottlenecks in the supply chain network and eliminating inefficiencies, companies can significantly reduce expenses. Streamlined logistics within the supply chain network mean lower transportation costs and quicker turnaround times. These savings can then be passed on to customers or reinvested into the business for further growth.

Inventory management is another area where optimization pays off. Balancing stock levels within the supply chain network to meet demand without overstocking minimizes holding costs and reduces the risk of obsolescence. Smart inventory strategies ensure products are available within the supply chain network when needed without tying up too much capital.

Customer Satisfaction

A well-optimized supply chain leads to better customer experiences. Quick, reliable delivery times, bolstered by an efficient supply chain network, make a positive impression, encouraging repeat business. Accurate order fulfillment rates go up with improved processes, which means fewer returns and complaints.

Moreover, transparent supply chains allow customers to track their orders in real-time, providing a sense of security and trust in the brand. This level of service is often what sets companies apart in a crowded marketplace.

Continuous Improvement

The market never stands still, and neither should supply chain strategies. Continuous improvement is essential for adapting to changing consumer demands and technological advancements. Regular analysis helps identify new trends early on so that businesses can adjust accordingly.

Investment in technology plays a key role here. Tools like AI and machine learning offer predictive insights that can transform supply chain management from reactive to proactive stances. They enable smarter decision-making that keeps networks resilient in the face of disruption.

Strategies for Network Enhancement

Location Selection

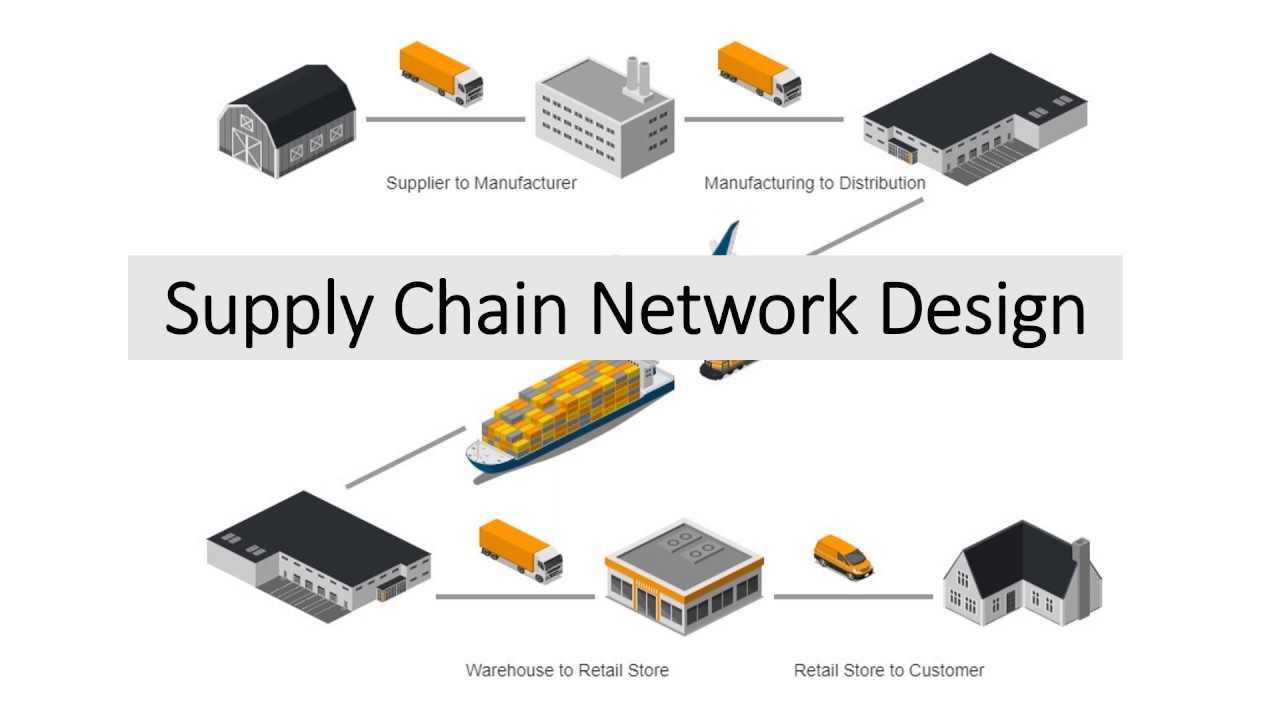

Strategic positioning of warehouses and distribution centers is crucial in network optimization. Choosing the right locations can significantly reduce transportation costs and improve delivery times. Companies must consider factors like proximity to key markets, infrastructure quality, and labor availability. They should also assess local regulations that might impact operations.

Optimal locations enable quicker response to customer demands, enhancing satisfaction. Businesses often use geographic information systems (GIS) to analyze spatial data when selecting sites. This technology helps identify areas with the best combination of accessibility, cost efficiency, and risk mitigation.

Data Analysis

Robust data analysis is vital for pinpointing inefficiencies within a supply chain network. By leveraging advanced analytics, companies can gain insights into every aspect of their operations. This includes inventory levels, supplier performance, and customer buying patterns.

Through this analysis, businesses can identify bottlenecks and areas where resources are underutilized. They can then implement targeted improvements such as better inventory management or more efficient routing. Predictive analytics also plays a role in forecasting demand and adjusting strategies accordingly.

Strategy Adjustment

Supply chains are dynamic; they require regular reviews to ensure they remain aligned with business goals and market conditions. This means periodically reassessing the network design and making necessary adjustments. Such assessments might lead to changes in supplier relationships, investment in new technologies, or shifts in inventory strategy.

Adapting to changes quickly is a competitive advantage. It allows businesses to capitalize on new opportunities and mitigate risks associated with market volatility or supply disruptions. Regular strategy updates help maintain an optimized supply chain that supports business growth and resilience.

Embracing Technological Advancements

IoT Integration

Businesses are rapidly integrating Internet of Things (IoT) devices and sensors to gain real-time visibility into their supply chains. These tools track goods from production to delivery, providing valuable data on inventory levels and shipment locations. They enable companies to respond swiftly to unexpected changes in demand or supply chain disruptions.

Sensors in manufacturing facilities monitor equipment performance, predict maintenance needs, and ensure product quality. This level of oversight leads to significant improvements in operational efficiency. With better inventory management, businesses avoid overstocking or stockouts, aligning closely with customer demands.

Predictive Analytics

The use of predictive analytics transforms how companies anticipate future trends and manage risks. By analyzing vast amounts of historical data, these solutions forecast customer buying patterns and market shifts with remarkable accuracy. Businesses can then adjust their production schedules accordingly.

This proactive approach reduces waste and enhances sustainability in the supply chain. Companies that leverage predictive analytics can make informed decisions that protect them from volatility in the market. They also cater more effectively to consumer preferences, which can be a substantial competitive advantage.

Blockchain Exploration

Blockchain technology is gaining traction as a means to bolster transparency and security within supply chains. By creating an immutable ledger of transactions, all parties involved—from suppliers to consumers—can trace the journey of a product with confidence.

This level of transparency helps businesses detect and prevent fraud, ensuring that products are authentic and ethically sourced. It also simplifies the reconciliation process in financial transactions and improves compliance with regulatory standards. As a result, trust is built not just within the company but also with customers who value ethical practices.

Centralized Management Adoption

Single Source

Centralized management acts as a single source of truth for supply chain data. This unified approach enhances decision-making. Teams access consistent information, reducing errors and speeding up responses to market changes. It also streamlines collaboration, as everyone refers to the same data set.

Centralization allows for real-time visibility into inventory levels and logistics operations. Decision-makers can quickly identify issues and opportunities, leading to more effective strategies.

Coordination Benefits

With centralized management, coordination across the supply chain improves significantly. Different components of the supply chain, such as procurement, manufacturing, and distribution, can align their activities more effectively. This alignment reduces bottlenecks and ensures that products move smoothly from suppliers to customers.

It also enables better communication between departments. They can anticipate demand fluctuations together and adjust their plans accordingly. Enhanced coordination leads to a more resilient supply chain, capable of withstanding disruptions.

Automated Reporting

Automated reporting is another advantage of centralized management. Systems generate reports on key performance indicators (KPIs) without manual intervention. This automation saves time and reduces the likelihood of human error in reporting.

Alerts notify managers about deviations from KPI targets immediately. They can take corrective actions swiftly to keep the supply chain operating at optimal levels. Automation also provides historical data for trend analysis, helping to predict future challenges and opportunities.

Efficiency Gains

Centralized management systems lead to significant efficiency gains. By automating tasks like data collection and report generation, companies can focus on strategic activities rather than administrative work.

These systems often include advanced analytics capabilities. They turn vast amounts of data into actionable insights, driving continuous improvement in the supply chain.

Multichannel Approach Benefits

Market Expansion

Multichannel distribution strategies expand market reach. They allow businesses to connect with more customers across various platforms. By utilizing both online and physical stores, companies tap into diverse consumer bases. This approach adapts to different shopping preferences, ensuring products are accessible wherever customers shop.

Customers benefit from the flexibility of purchasing through their preferred channel. They can buy online with the convenience of home delivery or visit a store for immediate pickup. This versatility caters to individual needs and boosts customer satisfaction.

Resilience Building

A multichannel strategy creates resilience against disruptions. If one channel faces issues, such as a physical store closure due to unforeseen events, other channels remain operational. This redundancy ensures continuous product access and mitigates losses.

Businesses that rely on a single channel are at greater risk when disruptions occur. Those with multiple channels can redirect resources and maintain operations smoothly. This adaptability is crucial in today’s fast-paced, unpredictable market environment.

Consistency Maintenance

Ensuring consistent service across all channels is key for customer satisfaction. Customers expect the same level of quality and availability whether they shop online or in-store. A seamless experience builds trust and encourages repeat business.

Inconsistencies can lead to frustration and drive customers away. Therefore, businesses must manage inventory effectively to provide reliable product availability across all platforms. This commitment to consistency solidifies brand reputation and fosters loyalty among consumers.

Diversifying Supplier Networks

Risk Mitigation

Businesses must reduce reliance on single suppliers to safeguard against disruptions. Diversifying supplier networks is a strategic move to mitigate risks. It ensures continuity when one source faces issues, like natural disasters or political unrest. Companies with multiple suppliers can quickly pivot, maintaining supply chain operations without significant delays.

They avoid the pitfalls of having all eggs in one basket. This approach spreads the risk across various trading partners and geographical locations. It minimizes the impact of any single point of failure within the supply network.

Market Responsiveness

A diverse supplier base enhances a company’s ability to respond to market changes. With access to multiple sources for raw materials and other goods, businesses can adjust more easily to demand patterns. They capitalize on opportunities or navigate challenges swiftly.

This flexibility is vital in today’s fast-paced markets. Companies can shift orders between suppliers based on factors such as production capacity, transportation costs, and lead times. Such agility in logistics allows for better alignment with consumer needs and market dynamics.

Competitive Advantage

Building strong relationships with a variety of suppliers fosters competitive pricing and quality assurance. By engaging with multiple sources, companies encourage competition among their suppliers. They gain leverage in negotiations, which can result in better terms and cost savings.

These partnerships also drive innovation and improvement in products and services. Suppliers are motivated to provide superior offerings to maintain their business with the company. This dynamic contributes to a robust supply chain network that supports long-term growth and success.

Strategic Positioning

Establishing a diversified supplier network positions businesses strategically for future expansion. It lays the groundwork for entering new markets or scaling operations efficiently. Companies can tap into their broad network to support growth initiatives without over-relying on existing distribution centers or supply channels.

They are better equipped to handle fluctuations in supply and demand, avoiding excess inventory or stockouts. A well-optimized chain network becomes a powerful asset that underpins all facets of supply chain logistics.

Overcoming Optimization Challenges

Data Silos

Data silos pose a significant hurdle in supply chain network optimization. They create information bottlenecks, hindering the flow of critical data. To break down these barriers, companies can invest in integration technologies. These tools help unify disparate data sources, enabling better decision-making.

Companies may also adopt advanced analytics to glean insights from consolidated data. This approach leads to more informed strategies and a sharper competitive edge.

Visibility Gaps

Lack of visibility across the supply chain can derail optimization efforts. It’s crucial to implement systems that provide real-time tracking and monitoring. Solutions like IoT devices and cloud-based platforms offer end-to-end visibility.

With improved oversight, businesses can anticipate disruptions and adjust operations swiftly. This agility reduces downtime and enhances overall efficiency.

Change Resistance

Organizational resistance to change can stifle improvement initiatives. To counter this, fostering a culture of continuous improvement is essential. Leaders should communicate the benefits of optimization clearly, linking them to personal and company-wide gains.

Engaging employees through training programs ensures they are equipped with the skills needed for new systems. Stakeholder engagement is vital; it encourages buy-in and eases the transition towards optimized processes.

Cost Management

High storage costs can eat into profits and diminish the value of optimization efforts. Strategies such as just-in-time inventory help minimize unnecessary stockpiling, reducing storage expenses.

Optimizing warehouse layouts and implementing automated storage solutions can lead to significant cost savings. These measures streamline operations and free up valuable resources for other strategic investments.

Key Factors in Optimization Success

Clear Objectives

Supply chain optimization hinges on well-defined goals. Companies need to pinpoint what they aim to achieve, whether it’s enhancing overall efficiency or boosting customer satisfaction. These objectives guide decision-making and offer a benchmark for success. For instance, if the goal is to reduce delivery times, strategies might include optimizing routes or improving inventory visibility.

Leaders must set specific targets, like increasing order fulfillment accuracy by 10%. Concrete goals not only clarify the direction but also motivate teams to push for better performance.

Leadership Commitment

The drive for supply chain improvement must start at the top. Senior leadership’s commitment is vital as it fuels the entire initiative. They provide resources, remove obstacles, and foster a culture that values continuous improvement.

Cross-functional teams play a pivotal role here. Bringing together experts from various departments ensures diverse perspectives and holistic solutions. This collaboration can lead to innovative strategies that meet complex customer expectations without compromising quality.

Flexibility and Scalability

A rigid supply chain can hinder growth and adaptation. Therefore, flexibility in design is non-negotiable. It allows businesses to adjust quickly to market changes, new regulations, or unexpected disruptions.

Scalability is equally critical. As companies grow, their supply chains should expand seamlessly without sacrificing efficiency or service levels. Planning for scalability involves assessing potential future needs and incorporating them into current designs.

Measuring Optimization Outcomes

KPI Implementation

To gauge the effectiveness of supply chain network optimization, businesses must rely on key performance indicators (KPIs). These metrics act as navigational beacons, offering clear insights into operational efficiency and cost savings. It’s essential to select KPIs that align with specific business goals.

Inventory levels, order fulfillment rates, and transportation costs are common KPIs. They provide a snapshot of system performance. Companies often track these metrics before and after implementing optimization strategies to measure improvements.

Benchmarking Success

Benchmarking against industry standards is another critical step in measuring outcomes. It helps companies understand where they stand in comparison to competitors and best practices. This process involves collecting data on similar companies and comparing it to one’s own performance metrics.

For instance, if a company reduces its inventory carrying costs by 15% after optimizing its network, but the industry average is a 20% reduction, there’s room for further improvement. Such comparisons spur continuous advancement.

Continuous Monitoring

Optimization isn’t a one-time event; it requires ongoing attention. Continuous monitoring ensures that supply chains adapt to changing conditions and maintain peak performance over time. Feedback loops are vital for this ongoing process, allowing for quick adjustments when needed.

Real-time inventory tracking systems play a significant role here. They offer up-to-the-minute data on stock levels across different locations, which can prompt immediate action when discrepancies arise.

Case Study Insights

Real-world examples underscore the value of meticulous measurement in optimization projects. For instance, a retail company may implement an advanced inventory tracking system to reduce overstock situations. By closely monitoring inventory turnover ratios before and after the change, they can quantify the impact of their efforts.

In another success story, a manufacturer might streamline their supplier network based on strategic KPIs like lead time reduction and quality improvements. The results often include faster production cycles and fewer defects which directly translate into better customer satisfaction scores.

Closing Thoughts

Optimizing your supply chain network isn’t just about keeping pace; it’s about setting the standard. You’ve seen how strategies like embracing tech and diversifying suppliers can steer your operations towards efficiency and resilience. The benefits are clear: streamlined processes, reduced costs, and a robust system that withstands disruptions. Your journey to optimization reflects a commitment to excellence, ensuring that every link in your chain is strong, reliable, and ready for the future.

Take action now. Review your current network, apply these strategies, and start measuring the outcomes. Remember, optimization is continuous; there’s always room for improvement. By enhancing your supply chain network today, you’re not just solving problems—you’re driving growth and success for tomorrow. Ready to lead the charge? Let’s optimize.

Frequently Asked Questions

What are the main benefits of supply chain network optimization?

Optimizing a supply chain network enhances efficiency, reduces costs, improves delivery times, and increases customer satisfaction by ensuring the right products reach the right place at the right time.

How can technology improve supply chain optimization?

Incorporating advanced technology like AI and machine learning helps predict demand, automate processes, and streamline operations for more efficient supply chain management.

Why is centralized management crucial in supply chain networks?

Centralized management provides a unified view of the supply chain, allowing for better coordination, reduced redundancies, and improved decision-making across all channels.

What advantages does a multichannel approach offer to supply chains?

A multichannel approach diversifies sales and distribution channels, mitigating risks and ensuring that disruptions in one channel do not severely impact overall operations.

How does diversifying supplier networks benefit a company?

Diversification of supplier networks protects against unforeseen disruptions by spreading risk across multiple sources, ensuring continuous supply even if one supplier faces challenges.

What are some common challenges in optimizing supply chain networks?

Challenges include dealing with complex data sets, managing ever-changing market demands, adapting to new technologies, and aligning diverse stakeholder interests within the network.

Which key factors contribute to successful supply chain optimization?

Success hinges on accurate data analysis, effective communication among stakeholders, adaptability to market changes, and continuous improvement based on performance metrics.