Ever wondered how your favorite products, protected by premier protective packaging solutions like cartons, arrive at your doorstep in pristine condition through shipments? The secret lies in effective packaging strategies using cartons for delicate items to minimize product damage during shipping and reduce damaged products in shipments. In today’s fast-paced e-commerce world, businesses are constantly seeking innovative packaging solutions to ensure their goods, packaged in premier protective packaging and cartons, withstand the journey from warehouse to customer shipments. This blog post dives into the heart of packaging excellence, exploring techniques and tips with cartons and stretch wrap that can significantly reduce the risk of shipping damages during shipment transit. From selecting the right materials to understanding the logistics behind secure packaging, including cartons, shipment package, and pallet, we’ve got you covered. Whether you’re a small business owner looking to improve your shipping process to reduce transit damage or a curious consumer interested in the behind-the-scenes of product delivery, this guide is your go-to resource for all things packaging, shipment, and package protection.

Key Takeaways

- Recognize the common causes of shipping damage to better protect your products, focusing on the importance of protective packaging as a first line of defense.

- Always select the correct box size for your product; too large can lead to movement and shipping damages, while too small can cause pressure damage. Opt for premier protective packaging solutions to ensure your package remains secure.

- Consider investing in custom packaging solutions, which not only minimize the risk of damage but also enhance brand perception.

- Implement impact indicators on your packaging solutions to monitor and reduce mishandling during transit, serving as a deterrent against rough handling.

- Make it a habit to collect and analyze shipping damage data related to packaging solutions. This information is crucial for identifying patterns and making informed improvements.

- Embrace a culture of continuous improvement in packaging strategies. Regularly review and update your practices to keep up with new technologies and materials that could further reduce the risk of product damage.

Understanding Shipping Damage Causes

Handling Processes

ting and dropping are common handling processes that often lead to package damage. During the sorting phase, packages go through numerous transitions, moving from one conveyor belt to another. This process can be harsh on packages, especially if they’re fragile or not properly secured, leading to transit damage.

Dropping occurs more frequently than many might expect. It happens during loading and unloading, and even during sorting when packages accidentally fall off conveyors, leading to transit damage. These drops, even from low heights, can cause significant product damage if the packaging isn’t designed to absorb shocks.

Cargo Movement

The impact of cargo movement within trucks, leading to transit damage, is another major factor affecting product safety. As vehicles navigate turns, accelerate, or brake, the contents inside can shift, potentially causing transit damage. Without proper stabilization, this movement can lead to transit damage.

Packages that aren’t firmly secured with dunnage (padding materials) or aren’t palletized correctly tend to move more freely inside the truck, increasing the risk of transit damage. This freedom increases their chances of colliding with other packages or the truck’s interior walls, leading to damage.

Internal Cushioning

Inadequate internal cushioning plays a critical role in shipping damage. Items inside a package need protection against external forces they encounter during transit. This includes impacts from drops, vibrations from travel, and pressure from other packages stacked on top, all contributing to transit damage.

Without sufficient cushioning materials like bubble wrap, foam inserts, or air pillows, products are vulnerable to transit damage such as scratches, dents, and breakages. The choice of cushioning material should match the product’s sensitivity to ensure it arrives at its destination undamaged.

Importance of Protective Packaging

Shock Absorption

Protective packaging plays a crucial role in absorbing shocks and vibrations during transit. These forces, if not mitigated, can severely damage products, especially delicate items. Proper packaging acts as a buffer, safeguarding the contents from transit damage and the rigors of shipping.

Materials like bubble wrap and foam inserts are designed to dissipate energy, ensuring that impacts do not transfer directly to the product, thereby preventing transit damage. This is particularly important for electronics and glass items that can easily crack or break upon impact, preventing transit damage.

Material Variety

A wide range of protective packaging materials is available, each suited to different types of products and shipping conditions to prevent transit damage. Understanding these options allows businesses to choose the right packaging for their specific needs.

- Bubble wrap offers lightweight cushioning, ideal for smaller items.

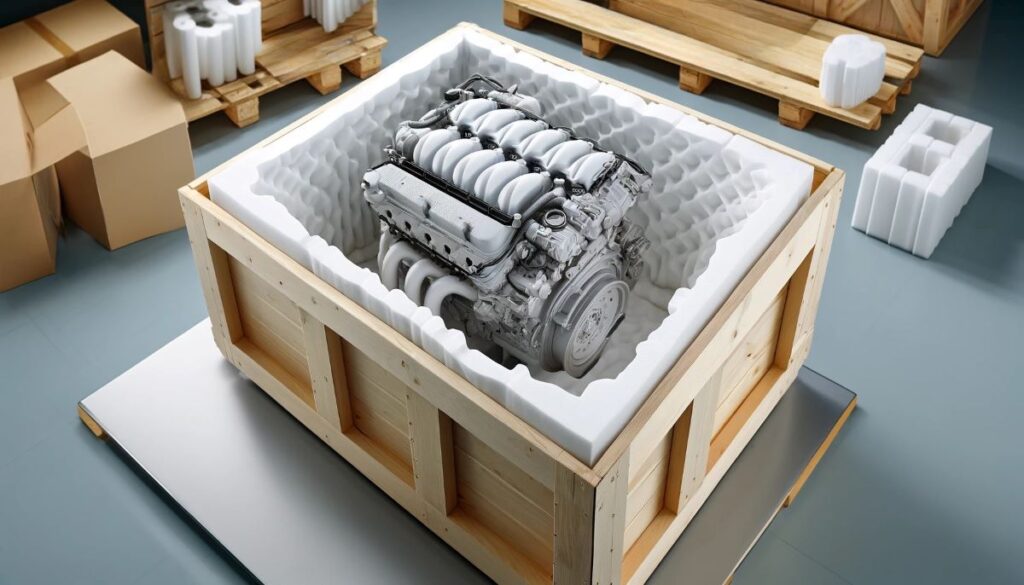

- Foam inserts can be custom-shaped to fit around more complex products.

- Corrugated cardboard dividers protect against scratches and provide structural support.

Selecting the appropriate material minimizes risk and ensures that items arrive in pristine condition.

Customization

Customizable protective features significantly enhance product safety during shipping. Tailoring protection to fit the product’s size, shape, and vulnerability points addresses specific risks more effectively than one-size-fits-all solutions.

For instance, heavy-duty items might require thicker corrugated boxes with reinforced corners. Meanwhile, delicate items benefit from multiple layers of soft padding and snug-fitting foam. This level of customization not only prevents damage but also reflects positively on the brand’s commitment to quality.

Selecting the Correct Box Size

Box Dimensions

Choosing the right box size is crucial for minimizing product movement during shipping. Products should snugly fit within their boxes, leaving just enough room for protective materials. This approach significantly reduces the chances of items shifting and sustaining damage.

Boxes come in various sizes, making it easier to find a perfect match for any product. It’s essential to measure your items and select a box that accommodates them plus a little extra space for cushioning. This strategy ensures products arrive in top condition, boosting customer satisfaction.

Empty Space

Minimizing empty space in packaging is not only about protecting the item but also about being cost-effective. Oversized boxes with too much void lead to unnecessary movement and potential harm to the contents. Moreover, they require more filler material, which can increase both weight and shipping costs.

To avoid these issues, use filler materials wisely to occupy any gaps without overstuffing. Properly filled boxes maintain their shape better and withstand external pressures during transit. They also prevent items from colliding with each other or the box walls, further reducing the risk of damage.

Environmental Impact

Using appropriately sized packaging has significant environmental benefits. It reduces waste by minimizing the need for excess packing materials and lowering the carbon footprint associated with transporting lighter, more compact packages.

Smaller boxes mean more items can be shipped together, decreasing the number of trips required to deliver goods. This efficiency not only cuts down on emissions but also on shipping costs, presenting an economic advantage for businesses. By selecting the correct box size, companies demonstrate their commitment to sustainability and responsible resource usage.

Benefits of Custom Packaging

Tailored Fit

Custom packaging solutions are crafted to accommodate the unique dimensions and shapes of products. This precision ensures each item sits snugly within its container, vastly reducing movement during transit.

The design process involves measuring product dimensions accurately. It then tailors the packaging to these specifications. Such meticulousness significantly decreases the likelihood of damage because it eliminates excess space where items could jostle or collide.

Branding Boost

Using custom designs for packaging turns each shipped product into a branding opportunity. The exterior of packages is no longer just a shell but a canvas for marketing messages and company logos.

This strategy enhances brand recognition. Customers often perceive custom-designed packages as more premium than standard ones. It creates a memorable unboxing experience that encourages social media sharing and word-of-mouth promotion.

Cost Efficiency

While initial costs for custom packaging might seem higher, long-term savings are substantial. By fitting products perfectly, companies use less filler material, which reduces both material costs and shipping weight.

Reduced damage rates mean fewer returns and exchanges. This outcome not only saves on the cost of processing returns but also preserves customer satisfaction and loyalty. Over time, investing in custom packaging proves to be a cost-effective strategy for businesses serious about minimizing product damage during shipping.

Implementing Impact Indicators

Monitoring Tools

Impact indicators serve as crucial monitoring tools in the logistics chain. They record and alert businesses to any mishandling that products may endure during shipping.

These devices attach directly to packages, making it clear when an item has experienced forces beyond a preset threshold. This immediate feedback allows companies to take action, whether it involves inspecting goods for damage or addressing concerns with shipping partners. By implementing these indicators, businesses can ensure the safety and integrity of their products from warehouse to customer.

Deterrence Factor

The presence of impact indicators on packaging plays a significant role in deterring mishandling.

When handlers see these devices, they understand that their actions are being monitored. This awareness often leads to more careful handling of packages, reducing the likelihood of damage. The psychological effect of knowing that mishandling will be detected and could lead to accountability measures is powerful. It encourages a culture of responsibility among all parties involved in the shipping process.

Process Improvement

Beyond their immediate benefits, impact indicators are invaluable for identifying weaknesses in the shipping and handling process.

Collecting Shipping Damage Data

Data Collection

After implementing impact indicators, the next critical step is systematically collecting data on shipping damages. This involves recording each incident where a product arrives damaged.

Businesses should track the date, shipping route, packaging used, and nature of the damage. This information becomes invaluable over time. It helps identify whether certain products are more prone to damage or if specific routes result in higher incidents of damage. Patterns begin to emerge, guiding businesses on where improvements are necessary.

Analyzing Trends

With a robust dataset, companies can move to the analysis phase. Here, they look for correlations between packaging choices and damage rates.

For instance, they might discover that double-walled boxes significantly reduce damage for fragile items. Or, that using foam inserts instead of bubble wrap better protects contents during transit. By understanding these trends, businesses can make informed decisions about their packaging strategies. This not only minimizes product damage but also reduces waste and saves costs in the long run.

Negotiating with Carriers

Armed with concrete data on shipping damages, businesses are in a stronger position to negotiate with shipping companies. They can present their findings to carriers and discuss ways to minimize product damage.

This could lead to better handling instructions being followed or even preferential shipping rates for demonstrating proactive measures to reduce claims. In some cases, it might prompt a review of transportation routes or methods to ensure products are delivered in the best condition possible.

Mitigating Ecommerce Shipping Risks

Reliable Carriers

Choosing reliable carriers is crucial. Businesses must research and select shipping partners known for their careful handling and timely delivery. This step significantly reduces the chances of products being damaged during transit.

Carriers with robust tracking systems allow both the seller and buyer to monitor shipments. This transparency can alleviate concerns and provide evidence in case something goes wrong.

Packaging Solutions

Investing in quality packaging is non-negotiable. E-commerce businesses should use durable materials that can withstand the rigors of the shipping process. Bubble wrap, foam inserts, and sturdy boxes are essential.

Custom-sized packaging can also prevent items from moving around during transport. This tailored approach minimizes damage and can be cost-effective in the long run.

Clear Communication

Transparent communication with customers about shipping practices builds trust. Informing buyers about how items are packaged and shipped manages their expectations.

Updates regarding the status of their shipment foster a positive buying experience. It shows that the business values customer satisfaction and is proactive in addressing potential issues.

Return Policies

A fair return policy is vital for handling incidents where products do arrive damaged. Clearly outlining steps customers need to take to return or exchange an item simplifies the process for both parties.

This policy should be easy to find and understand on the business’s website. It reassures customers that they will not be left at a disadvantage if their purchase is not in perfect condition upon arrival.

Insurance Coverage

Securing insurance for shipments protects against financial loss from damaged goods. It provides a safety net for businesses, ensuring they can refund or replace items without significant economic impact.

Insurance also signals to customers that their satisfaction is a priority. It demonstrates a commitment to making things right, regardless of unforeseen shipping challenges.

Preventive Steps for Damage Control

Staff Training

Regular training sessions for staff on proper packaging techniques play a crucial role in minimizing damages. These sessions can cover everything from the basics of box selection to the nuances of cushioning and sealing. By understanding the importance of each step in the packaging process, employees are better equipped to pack items in a way that reduces their exposure to damage.

Staff should also be educated on the significance of handling instructions and labels. This ensures that everyone involved in the shipping and handling process is aware of the need for special care when necessary.

Standardized Procedures

Adopting standardized packaging procedures ensures consistency across all packages. This uniformity helps in maintaining a high level of protection for every item shipped, significantly reducing the likelihood of damaged products.

Standardization includes specifying the types of boxes, cushioning materials, and seals that should be used based on the item’s size, weight, and fragility. It also involves setting clear guidelines on how to properly use these materials to achieve optimal containment force, which is key to preventing items from moving inside their boxes during transit.

Durable Materials

The choice of packaging materials directly impacts an item’s integrity throughout its journey. Using durable materials and strong seals can significantly enhance package integrity, offering better resistance against rough handling and environmental factors.

Materials such as high-quality cardboard boxes, bubble wrap, and packing peanuts provide excellent cushioning. Meanwhile, heavy-duty tapes ensure that boxes remain securely sealed. Investing in these materials might increase initial costs but will pay off by reducing financial loss due to damaged items.

Insurance Coverage

Despite taking all preventive measures, some degree of risk always remains. Therefore, securing insurance coverage for shipped goods adds an extra layer of protection against unforeseen damages.

Insurance not only offers financial compensation but also demonstrates a commitment to customer satisfaction. When customers know that their purchases are insured, it builds trust in your business’s shipping practices.

Continuous Improvement in Packaging

Feedback Loop

Manufacturers and distributors can significantly enhance customer satisfaction by establishing a robust feedback loop. This process involves actively seeking and incorporating customer feedback on packaging effectiveness.

Such feedback helps identify common issues with packages during shipping, such as damage due to inadequate packaging material or structural failures. By addressing these concerns, companies can adapt their packaging strategies to prevent future incidents. This continuous loop of feedback and improvement ensures that packaging methods evolve alongside customer expectations and product needs.

Material Testing

Regular evaluation and testing of packaging materials are crucial for minimizing product damage. This step goes beyond selecting the right type of carton or stretch wrap; it involves rigorous testing under various conditions to simulate the shipping process.

Testing different combinations of materials, like kraft paper for cushioning inside cartons or stronger pallets for heavy goods, helps pinpoint the most effective solutions. It also identifies opportunities for enhancing the structural integrity of packages, ensuring they withstand the rigors of transit.

Technology Updates

Staying abreast of advancements in packaging technology is vital for any business looking to reduce product damage during shipping. New materials and solutions emerge regularly, offering better protection or sustainability profiles than existing options.

For instance, innovations in stretch film technology can provide superior strength and flexibility, reducing the risk of tears or punctures. Similarly, developments in smart packaging can alert carriers to mishandle or conditions that could compromise the quality of sensitive products like food. Embracing these technologies not only improves product safety but also demonstrates a commitment to using cutting-edge solutions for customer benefit.

Closing Thoughts

Shipping damage is a real headache, but with the right strategies, you can significantly reduce the risk. From understanding what causes damage to implementing impact indicators and improving packaging continuously, every step counts. Your focus on protective packaging, selecting the right box size, and custom solutions not only minimizes damage but also enhances customer satisfaction. Remember, collecting data on shipping damages and taking preventive steps are key to refining your approach. Keeping ecommerce risks at bay requires constant vigilance and adaptation.

Now’s the time to put these insights into action. Review your current packaging process, identify areas for improvement, and start making changes today. By prioritizing product safety during shipping, you’re not just saving costs—you’re building trust with your customers. Don’t let shipping damages be the downfall of your business; take control and make a difference now.

Frequently Asked Questions

What are the main causes of shipping damage?

Shipping damage often results from inadequate packaging, mishandling, environmental factors, and using incorrect box sizes. Understanding these causes is crucial for prevention.

Why is protective packaging important?

Protective packaging absorbs shocks and prevents product movement inside the box, significantly reducing the risk of damage during transit.

How does selecting the correct box size impact shipping safety?

Using the right box size minimizes empty space, preventing items from moving around during shipping, which can lead to less product damage.

What are the benefits of custom packaging for products?

Custom packaging not only ensures a perfect fit for your product but also enhances brand perception and customer experience while minimizing damage risks.

How do impact indicators work in minimizing shipping damages?

Impact indicators detect and record mishandling during shipping by showing when a package has been dropped or struck, encouraging better handling practices.

Why is it important to collect data on shipping damages?

Collecting data helps identify patterns in damages, enabling businesses to adjust their packaging strategies effectively to reduce future incidents.

What preventive steps can be taken to control product damage during shipping?

Implementing durable materials, securing items within boxes, using impact indicators, and continuously improving packaging based on feedback are key steps for damage control.