In the bustling world of e-commerce, micro-fulfillment centers, a form of infill warehouse development, are revolutionizing how businesses and logistics companies tackle the last mile of delivery by optimizing warehousing and warehouse space. These compact, tech-driven hubs, often referred to as micro warehousing, stand in stark contrast to sprawling warehouses and larger fulfillment centers, offering a nimble solution to meet the ever-accelerating consumer demand for rapid delivery from distribution and logistics centers. By embedding logistics centers and larger fulfillment centers in urban landscapes through infill warehouse development, they not only promise speed but also redefine efficiency in the supply chain as distribution centers. As we peel back the layers of these innovative logistics platforms, including micro warehousing and fulfillment centers, we’ll discover how they’re not just keeping pace with online shopping trends but actually setting a new standard for ecommerce businesses, with products flying off the shelves.

Key Takeaways

- Micro-fulfillment centers, a form of warehousing for ecommerce businesses and logistics companies, are revolutionizing the supply chain by bringing inventory closer to consumers and store locations, resulting in faster delivery times and reduced shipping costs.

- The surge in e-commerce has propelled the popularity of micro-fulfillment centers, offering ecommerce businesses and logistics companies a competitive edge in meeting customer expectations for rapid delivery and efficient warehousing.

- Strategic placement of micro-fulfillment centers, serving as warehousing and store sites for various brands within urban areas, can significantly improve delivery efficiency, underscoring the importance of location insights in their implementation.

- Companies, including various brands, can reap substantial benefits from micro-fulfillment, such as lower overhead costs and improved inventory management in warehousing and store operations, making them a smart investment for businesses looking to optimize their distribution networks.

- The integration of AI and automation within micro-fulfillment centers boosts efficiency and accuracy for warehousing, showcasing the potential of technology to enhance operational performance for brands.

- Collaborative shipping strategies that leverage micro-fulfillment can lead to more sustainable operations and cost savings, highlighting the value of partnerships in logistics.

Defining Micro-Fulfillment

Concept Overview

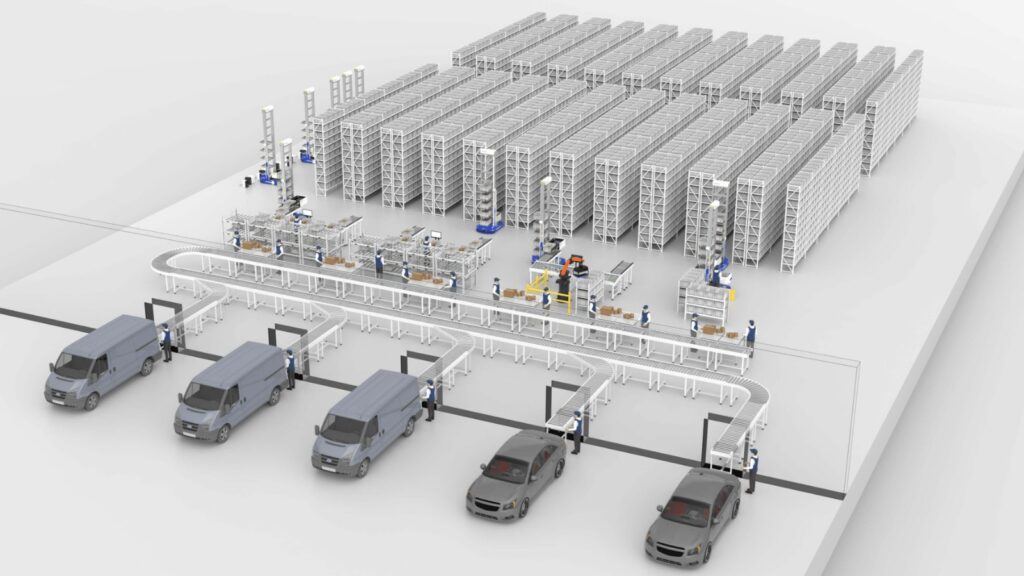

Micro-fulfillment centers (MFCs) are compact hubs designed to expedite the order fulfillment process. They sit at the intersection of speed and convenience in retail operations, utilizing fulfillment center innovations and micro warehousing strategies. Unlike traditional large-scale warehouses, micro-fulfillment centers (MFCs) occupy smaller footprints, often within urban areas. This strategic positioning reduces delivery times dramatically.

Businesses use these micro warehousing centers to store a limited range of products closer to end consumers. They can quickly process orders from fulfillment centers and micro warehousing, making them ideal for online shopping surges. Their small size doesn’t hinder efficiency in the micro warehousing fulfillment center; rather, it enhances it through advanced automation and robotics.

Size and Capacity

The typical size of an MFC, often used for micro warehousing, ranges from 10,000 to 50,000 square feet. This is a fraction of the size of larger fulfillment centers, often referred to as micro warehousing, that can span hundreds of thousands of square feet. Despite their modest scale, MFCs are highly optimized for space utilization in micro warehousing.

Shelving and storage units are designed to maximize vertical space, often supported by robotic systems that retrieve items efficiently. These space-saving strategies allow MFCs to hold a surprising volume of stock relative to their footprint.

Retail Integration

In modern retail and e-commerce landscapes, MFCs play a pivotal role in meeting customer demands for speedy delivery. They act as local nodes that bridge the gap between online orders and physical product distribution.

Retailers integrate micro-fulfillment into their supply chains to ensure products are readily available near high-demand locations. This proximity allows for same-day or even two-hour delivery options — a service level that has become increasingly expected by consumers.

E-commerce Efficiency

For e-commerce players, micro-fulfillment solutions offer agility that traditional warehouses cannot match. They enable retailers to fulfill online orders with unprecedented speed, contributing significantly to customer satisfaction and loyalty.

MFCs also reduce shipping costs due to their proximity to customers. They streamline last-mile delivery — the final step in getting products into buyers’ hands — which is often the most expensive part of the shipping process.

By leveraging data analytics, these centers can predict buying patterns and stock products accordingly. This foresight minimizes overstocking and ensures hot-ticket items are always on hand.

Reasons for Rising Popularity

Cost Reduction

Micro-fulfillment centers (MFCs) are gaining traction as businesses seek to minimize last-mile delivery costs. These smaller, more localized distribution hubs allow for swifter delivery times, directly translating to reduced transportation expenses. MFCs often nestle within city limits, slashing the distance products travel to reach consumers. This proximity significantly cuts fuel and labor costs associated with delivery.

Retailers also save on inventory carrying costs. By holding less stock in each location, they reduce the capital tied up in unsold goods. These savings can be substantial when compared to traditional large-scale warehouses that serve broader regions.

Efficiency Gains

MFCs operate with heightened efficiency due to their size and technology integration. They utilize advanced robotics and software to expedite order processing, which means customers receive their purchases faster. This efficiency isn’t just about speed; it’s also about precision. With more sophisticated systems, MFCs make fewer errors in picking and packing orders, thus reducing the need for costly returns and exchanges.

The design of MFCs allows for flexible inventory management. Retailers can quickly adapt to changing consumer demand by stocking items that are more likely to be purchased in specific locales. This tailored approach ensures higher turnover rates and less dead stock.

E-commerce Influence

The rise of e-commerce giants has reshaped expectations around delivery times and service quality. Companies like Amazon have set a precedent for rapid fulfillment, compelling others in the logistics industry to follow suit or risk falling behind. The shift towards MFCs is partly an industry response to this new standard.

These e-commerce leaders often pioneer innovations that trickle down into wider use—such as sophisticated tracking systems or automated warehousing solutions—which are integral components of successful micro-fulfillment operations.

Location Insights

Urban Proximity

Micro-fulfillment centers (MFCs) thrive on proximity to consumers. By situating these facilities in urban locations, businesses slash transit times dramatically. This approach brings products closer to a vast customer base residing in population centers. Retailers leverage data to pinpoint optimal locations, ensuring MFCs are never too far from the end consumer.

Shorter distances mean faster delivery. It’s simple logistics that benefits both the business and its customers. These strategic placements also allow for a smaller footprint, as high storage density compensates for limited space.

Building Repurposing

Repurposing existing buildings is a smart strategy for establishing MFCs. Dark stores—retail outlets previously shuttered—are prime candidates for transformation into storage facilities. This not only saves on construction costs but also speeds up the setup process.

Retailers can breathe new life into these dormant spaces by converting them into efficient MFCs. The practice aligns with sustainability goals, reducing waste and resource consumption associated with new constructions.

Retail Integration

Integrating MFCs within or adjacent to retail stores offers numerous advantages. It streamlines operations by consolidating inventory management and distribution processes. Retailers benefit from having their products and the means to distribute them in one location.

This configuration enhances the synergy between online and brick-and-mortar sales channels. Stores double as distribution hubs, optimizing the last mile of delivery—a critical factor in customer satisfaction.

Company Advantages

Faster Fulfillment

Micro-fulfillment centers (MFCs) are revolutionizing how businesses manage inventory and fulfill orders. They concentrate on top-selling items, enabling companies to expedite delivery. Customers now enjoy receiving their products swiftly, often within the same day.

Businesses leverage MFCs for their proximity to consumers. This closeness allows for rapid order processing, which is crucial in today’s fast-paced market. The result? Enhanced customer satisfaction and repeat purchases.

Shipping Savings

Localized stock at MFCs slashes shipping costs significantly. By reducing the distance goods travel, businesses save on logistics expenses. This model contrasts with traditional warehouses that rely on extensive parcel shipments, often incurring hefty fees.

Retailers and ecommerce businesses see a direct impact on their bottom line with this approach. They can offer competitive pricing while maintaining profitability. Moreover, reduced shipping costs can be passed on to customers, fostering loyalty and boosting sales.

Market Adaptability

Emerging markets present unique challenges for companies aiming to establish a presence quickly. MFCs offer a solution with their rapid deployment and scalability. These centers can be set up in urban areas where space is at a premium, allowing brands to penetrate new markets effectively.

The adaptability of MFCs also extends to technology integration. Businesses can easily implement the latest systems for inventory management and order processing without significant downtime or disruption.

AI in Efficiency Boost

Inventory Optimization

Artificial intelligence (AI) transforms inventory management in micro-fulfillment centers (MFCs). It analyzes vast datasets to predict stock levels accurately. This prevents both overstocking and stockouts, balancing inventory to meet demand without excess. AI systems track item sales patterns, seasonality, and trends. They adjust inventory in real-time, ensuring optimal stock levels.

AI tools also streamline the restocking process. They identify which items to reorder and the best quantities. This precision cuts down on waste and storage costs. MFCs benefit from such efficiency, as space is at a premium.

Demand Forecasting

AI-driven forecasting tools are pivotal for demand prediction in MFCs. These tools analyze past consumer behavior and external factors like weather or holidays. They predict future demand with remarkable accuracy. With this information, MFCs can prepare for surges or slumps in product needs.

Forecasting ensures that popular items are always available, while less popular ones don’t take up valuable space. This level of demand anticipation enhances customer trust and loyalty. Companies can fulfill orders swiftly because they have the right products stocked at the right time.

Order Processing

Order processing speed and accuracy see significant improvements thanks to AI. Automation technology integrates with ordering systems to pick, pack, and ship items faster than ever before. Orders are processed with high precision, reducing errors that can lead to customer dissatisfaction.

AI systems learn from every order, becoming more efficient over time. They handle complex tasks like routing orders based on delivery schedules or customer priority. Quick and accurate order processing leads to faster delivery times—a key factor in customer satisfaction.

Collaborative Shipping Strategies

Logistics Integration

Micro-fulfillment centers (MFCs) are transforming logistics. They enable faster delivery times by being closer to customers. These small warehouses integrate into broader supply chain assets, enhancing the efficiency of shipping processes. As part of a collaborative shipping strategy, MFCs work in tandem with larger distribution centers. This dual approach streamlines inventory management and reduces the time it takes for online orders to reach consumers.

The synergy between MFCs and traditional warehousing allows retailers to offer same-day or next-day delivery. This is crucial in an era where online shopping demands speed. By optimizing warehouse space, businesses can keep popular items stocked at strategic locations. This reduces the distance covered during delivery, slashing shipping costs significantly.

Local Partnerships

Collaboration extends beyond warehousing. MFCs often partner with local delivery services for last-mile logistics. These partnerships foster community ties and support small businesses. They also lead to more efficient use of resources and personnel, cutting down on delivery times.

Local couriers know their areas well, navigating routes faster than national carriers might. By leveraging this knowledge, MFCs ensure that online orders arrive swiftly and accurately. Customers benefit from improved service, while retailers enjoy the loyalty such service inspires.

Environmental Impact

Collaborative strategies have a positive effect on the environment too. By reducing travel distances for deliveries, they lower carbon emissions associated with last-mile logistics. The use of infill warehouse development also contributes to this benefit by repurposing existing structures within urban areas rather than building new ones.

The proximity of MFCs to customers means fewer long-haul trips are necessary. This results in less fuel consumption and fewer greenhouse gases released into the atmosphere. Moreover, partnering with local services often involves smaller vehicles which are typically more fuel-efficient than large trucks.

Benefits and Drawbacks

Cost Savings

Micro-fulfillment centers (MFCs) offer substantial cost savings for businesses. They reduce the need for large, centralized warehouses by bringing inventory closer to the end consumer. This proximity cuts down on transportation costs and streamlines distribution. Retailers can save on labor costs as well, thanks to automated systems that handle sorting and packing of items.

Businesses that integrate MFCs often see a decrease in the amount of capital tied up in inventory. With products moving faster off the shelves, there’s less need to stockpile large amounts of goods. This approach helps companies maintain liquidity and invest in other areas of their operations.

Speed and Flexibility

Speed is a significant advantage when using MFCs. Consumers’ demands can be met with greater efficiency as items are stored nearer to where they are needed. Orders are processed quickly, often allowing for same-day delivery—a service that has become increasingly important to end consumers.

Flexibility is another key benefit. MFCs can be set up in various locations, such as urban centers or within existing retail spaces, making it easier to adapt to shifting market trends and consumer behaviors. The ability to scale operations up or down without major disruptions is a crucial factor for businesses aiming to stay competitive.

Initial Setup Costs

Despite their advantages, MFCs come with challenges. One significant drawback is the initial setup cost. Implementing an automated micro-fulfillment system requires considerable investment in technology and infrastructure. For some businesses, particularly small ones, this upfront expense can be prohibitive.

The reliance on advanced technology also introduces potential risks related to system failures or cyberattacks. These could lead to costly downtimes or security breaches, affecting both operations and consumer trust.

Technology Dependence

MFCs depend heavily on cutting-edge technology for their operations. While this automation increases efficiency, it also means that businesses must keep pace with rapid technological advancements to avoid obsolescence.

Training staff to operate these complex systems involves additional time and resources. Companies must consider these factors when evaluating the feasibility of adopting an MFC model.

Long-Term Impact

The long-term impact of MFCs on traditional warehousing is profound. By decentralizing distribution networks, they challenge established logistics practices. Traditional large-scale warehouses may need to evolve or risk becoming outdated as more nimble and responsive fulfillment methods gain traction.

Retailers embracing MFCs may also influence supplier relationships. Suppliers might need to adjust their production cycles and delivery methods to align with the just-in-time restocking processes favored by micro-fulfillment strategies.

Overcoming Challenges

Initial Investment

Micro-fulfillment centers (MFCs) require significant upfront costs. To manage this, companies can explore various financing options. Leasing equipment rather than purchasing can reduce initial expenditures. Implementing a phased approach allows for spreading out costs over time. It’s crucial to optimize the design of MFCs to maximize space and efficiency, which can offset some of the startup expenses.

Businesses might also consider government grants or subsidies if available. These can alleviate financial burdens and encourage innovation in supply chain logistics.

Technological Hurdles

The backbone of an MFC is its advanced technology. While setting up, businesses face challenges like integrating complex software systems and automating processes. The solution lies in partnering with tech firms that specialize in automation and robotics. These collaborations ensure access to the latest advancements and expertise.

Moreover, staff training is essential for smooth operations. Investing in employee development ensures they are adept at handling new technologies, which enhances overall productivity.

Continuous Innovation

For MFCs to remain competitive, they must embrace continuous innovation. This means regularly assessing and updating their technology stack to keep pace with industry changes. Staying ahead involves not just adopting new technologies but also refining operational processes.

Feedback loops are invaluable; they help understand customer expectations and adapt accordingly. Data analytics plays a key role here, providing insights into consumer behavior and helping tailor services to meet demand efficiently.

Partnerships Expansion

Expanding the capabilities of MFCs often requires forming strategic partnerships. Collaborations with local businesses can extend an MFC’s reach while maintaining swift delivery times. Similarly, alliances with tech companies can bring in cutting-edge solutions that propel efficiency scales.

These partnerships may also open avenues for shared knowledge and resources, further enhancing the potential of micro-fulfillment solutions.

Space Optimization

Finding enough space for an MFC within urban areas can be challenging due to high real estate prices and limited availability. Smart design is critical here; it ensures that every square foot is used effectively. For instance, vertical storage solutions can drastically increase capacity without needing more ground space.

Flexible processing areas allow for adjustments based on daily needs or seasonal fluctuations, ensuring space is never wasted.

Summary

Micro-fulfillment centers are revolutionizing how you receive goods, merging speed with convenience like never before. As we’ve explored, these hubs offer compelling advantages for companies and customers alike, from slashing delivery times to enhancing inventory management with AI. They’re not just a trend; they’re a glimpse into the future of retail logistics, balancing the scales between online and brick-and-mortar experiences.

Think about how this shift could streamline your shopping habits or boost your business. The potential is immense, but so are the challenges that need tackling head-on. It’s time to weigh the benefits against the drawbacks and decide if diving into micro-fulfillment aligns with your goals. Ready to take the leap? Your next step could redefine efficiency for your enterprise or simplify life in ways you’ve yet to imagine. Dive in, and let’s reshape the landscape of fulfillment together.

Frequently Asked Questions

What exactly are micro-fulfillment centers?

Micro-fulfillment centers are small-scale warehouse facilities located near consumers that speed up the process of picking and delivering online orders.

Why are micro-fulfillment centers becoming more popular?

They’re gaining traction due to their ability to reduce delivery times, lower shipping costs, and improve customer satisfaction by bringing products closer to the end consumer.

Where are micro-fulfillment centers typically located?

These centers are often situated in urban areas or attached to existing retail stores to ensure proximity to a large customer base.

How do companies benefit from micro-fulfillment?

Companies enjoy reduced last-mile delivery costs, faster response times, and increased inventory turnover thanks to these strategically placed hubs.

Can AI really boost efficiency in micro-fulfillment?

Absolutely! AI helps optimize inventory management, predict demand, and streamline order processing, making the whole system more efficient.

What’s collaborative shipping and how does it relate to micro-fulfillment?

Collaborative shipping involves multiple businesses sharing distribution resources like transportation or warehousing, which can include micro-fulfillment networks, to cut costs and environmental impact.

What are some benefits and drawbacks of micro-fulfillment?

Benefits include quicker deliveries and reduced costs. Drawbacks may involve high initial setup expenses and complex integration with existing supply chains.

What challenges do micro-fulfillment centers face and how can they be overcome?

Challenges include managing high upfront costs and integrating technology. Solutions lie in strategic planning, partnerships, and incremental tech adoption.