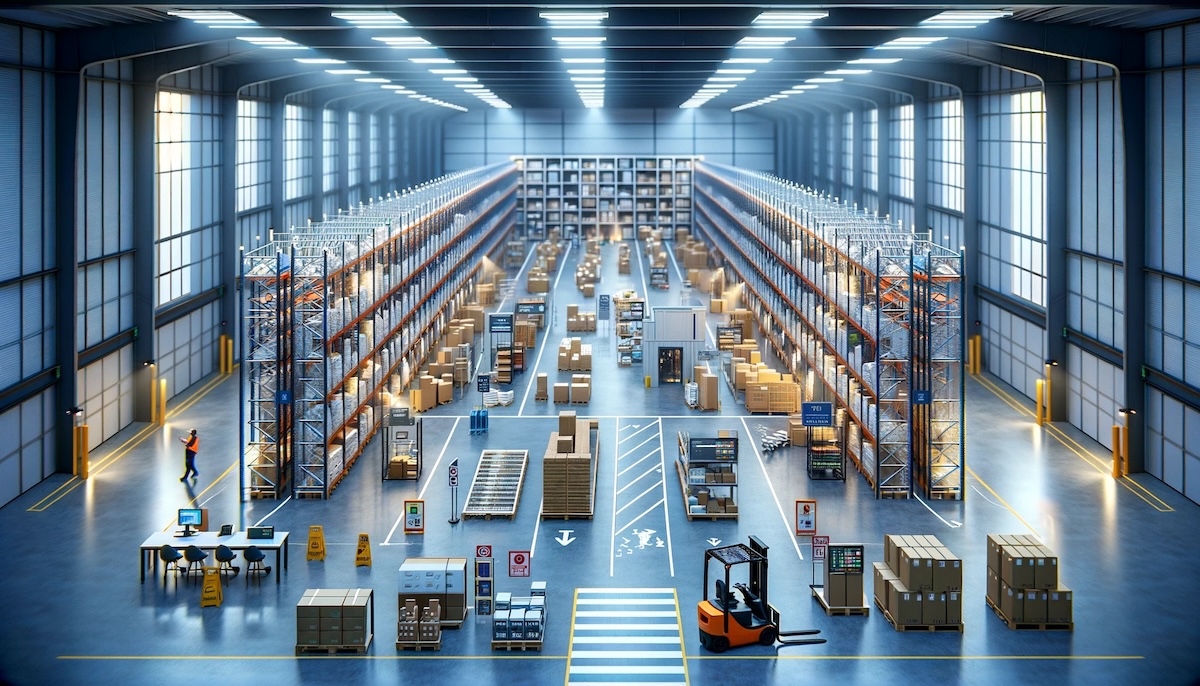

Did you know that over 80% of consumers expect a seamless, fast shipping process, including same-day delivery, when they order online from ecommerce companies that utilize fulfillment services and fulfillment warehouses? This staggering statistic highlights the critical role of fulfillment distribution centers, or warehouses, in shipping orders and stocking shelves for ecommerce companies in today’s e-commerce landscape. These hubs, known as fulfillment warehouses or distribution centers, are not just about storing products; they’re the backbone of delivering customer satisfaction and loyalty through ecommerce fulfillment services. By optimizing operations, leveraging advanced technology, and ensuring quick turnaround times, fulfillment distribution centers and warehouses play a pivotal role in keeping businesses ahead in the competitive market by providing essential ecommerce services to store and distribute products. Whether you’re a small startup or a large enterprise in ecommerce, understanding how these centers, including fulfillment warehouses and 3pl fulfillment services, operate can transform your supply chain efficiency and elevate your customer experience to new heights.

Key Takeaways

- Understanding the variety of services offered by fulfillment, 3pl, and distribution centers, including warehouses that store ecommerce goods, can help businesses streamline their operations and improve efficiency.

- Evaluating the pros and cons of different ecommerce fulfillment strategies, including 3pl services and warehouses, is crucial for businesses to align their distribution needs with their customer expectations and business goals.

- Enhancing customer experiences through efficient fulfillment practices, including services from warehouses and distribution centers, often managed by 3pl, leads to higher satisfaction rates and repeat business, making it a key area of focus for e-commerce and retail businesses.

- Adopting the latest technology and focusing on efficiency within fulfillment processes in distribution center warehouses and 3pl services can significantly reduce costs and improve order accuracy.

- Implementing sustainable fulfillment practices in distribution centers and warehouses, including the use of 3pl, is not only good for the environment but also resonates with the growing number of eco-conscious consumers, potentially boosting brand loyalty.

- Businesses should consider both global and local strategies in their fulfillment operations, utilizing distribution centers and warehouses, to effectively meet the demands of a diverse customer base and navigate the complexities of international shipping.

Key Services in Fulfillment Centers

Picking and Packing

Fulfillment centers, often referred to as warehouses, specialize in efficiently picking products from their vast inventories. They ensure that each order is accurately fulfilled. Workers use advanced systems to locate items quickly.

After picking, the packing process begins. Here, the focus is on protecting goods during transit. Materials like bubble wrap or air pillows are common. This step is crucial for e-commerce and B2B orders, where customer satisfaction hinges on receiving items undamaged from fulfillment warehouses, often involving a fulfillment center or distribution center.

Shipping Services

Shipping is the final step in the fulfillment process. Fulfillment warehouses, also known as distribution centers, partner with various carriers to offer flexible shipping options. This includes standard, expedited, and international shipping.

They leverage bulk shipping rates, making it cost-effective for businesses of all sizes. Tracking information is provided from the distribution center and fulfillment center, allowing both the business and its customers to monitor shipments in real-time.

Kitting Services

Kitting involves combining individual items into ready-to-ship packages in a fulfillment center. This service, provided by a fulfillment center, is vital for businesses that sell products requiring assembly or sold as a bundle.

It streamlines the order fulfillment process by reducing the number of shipments per order. Kitting also enhances inventory management in the fulfillment center by treating multiple SKUs as a single unit, simplifying stock level tracking.

Bulk Shipping

Bulk shipping services, often seen in B2B transactions, cater to large volume orders from fulfillment centers. These services reduce shipping costs significantly.

By consolidating orders into fewer shipments, fulfillment centers can offer more competitive rates to their clients. It’s not just about cost savings; bulk shipping also reduces the carbon footprint associated with transporting goods.

Inventory Management

Accurate inventory management is the backbone of any successful fulfillment center. It ensures that stock levels in the fulfillment center are consistently maintained, minimizing overstocking or stockouts.

Advanced software tracks inventory in real-time in the fulfillment center, providing businesses with up-to-date information on their product availability. This allows for better planning and forecasting in the fulfillment center, ensuring that they can meet customer demand without holding excessive inventory.

Exploring Distribution Center Offerings

Inbound Materials

Distribution centers play a crucial role in receiving inbound materials. They ensure that retailers can restock items efficiently.

When goods arrive, the center quickly processes them. This speed supports retailers needing to replenish their shelves. The centers use advanced systems to track inventory levels. They make sure that products are available when needed.

Just-In-Time Replenishment

Just-in-time inventory replenishment is another key service offered by distribution centers. This method helps businesses maintain optimal inventory levels.

It reduces the need for large warehouses. Businesses save on storage costs. Products arrive from the fulfillment center only as they’re needed, which minimizes overstocking issues. This approach ensures that products from the fulfillment center are fresh and in good condition for consumers.

Wholesale Distribution

Wholesale distribution within specific industries significantly impacts supply chain efficiency.

For example, in the pharmaceutical industry, distribution centers ensure timely delivery of medications to pharmacies. This precision is vital for patient care. Similarly, in the electronics sector, these centers manage the flow of components essential for manufacturing processes.

Comparing Pros and Cons

Cost Implications

Fulfillment centers and distribution centers serve different purposes, impacting storage costs. Fulfillment centers often charge for long-term storage, making them less ideal for items not moving quickly. Distribution centers, designed for bulk movements, offer potentially lower storage costs due to their focus on efficiently transferring goods rather than holding them.

Long-term storage in fulfillment centers can become costly, especially for products that do not turn over quickly. The fees associated with such storage can eat into the profit margins of businesses. In contrast, distribution centers typically handle larger volumes and move products more rapidly, reducing the need for extended storage and thus lowering costs.

Shipping Rates

Fulfillment centers shine when it comes to offering lower shipping rates due to their strategic locations closer to consumers. This proximity to the center allows for faster delivery times at reduced costs. Distribution centers, while excelling in handling large quantities of goods, may not offer the same level of shipping discounts due to their focus on bulk movement rather than direct-to-consumer delivery.

The benefits of reduced shipping rates from fulfillment centers are clear. They not only ensure customer satisfaction through timely delivery but also help businesses save on transportation costs. However, distribution centers can leverage competitive pricing for bulk movements, appealing to businesses dealing with large inventories.

Personalized Treatment

Industry-specific distribution provides personalized treatment of products, catering to unique requirements. This could include special handling or temperature controls not typically available in fulfillment centers. However, fulfillment centers may offer cost savings by standardizing processes across various types of items.

The trade-offs here are significant. On one hand, the customized approach of industry-specific distribution ensures that sensitive or specialized products are handled correctly, reducing the risk of damage and maintaining quality. On the other hand, the streamlined operations in fulfillment centers can lead to significant cost reductions but might not meet the specific needs of all products.

Enhancing Customer Experiences

Real-Time Tracking

Real-time inventory tracking stands as a cornerstone for customer satisfaction. It ensures that customers receive what they ordered accurately and promptly. This technology allows fulfillment centers to monitor stock levels in real time.

They can update customers on the availability of products instantly. This transparency reduces frustration and builds trust. Customers appreciate knowing the status of their orders without delays. They feel valued when businesses cater to their needs efficiently.

Software Solutions

histicated software platforms revolutionize how orders are processed. These systems streamline operations, making them faster and more reliable. They play a crucial role in minimizing errors during order fulfillment.

By automating processes, these platforms ensure that every order is handled with precision. This not only saves time but also significantly cuts down on operational costs. As a result, businesses can offer better services at competitive prices. Customers benefit from error-free transactions and swift deliveries, enhancing their overall shopping experience.

Efficient Processing

Efficient order processing fosters customer loyalty like nothing else. When consumers receive their purchases on time and as expected, they are more likely to return for more business. This reliability encourages a strong customer base.

Repeat business is crucial for growth in today’s competitive market. Fulfillment centers that prioritize efficient order handling see a notable increase in customer retention rates. They understand that satisfying existing customers is often more cost-effective than acquiring new ones.

Embracing Technology and Efficiency

Automated Storage

Fulfillment centers have significantly evolved with the integration of automated storage systems. These systems streamline order processing, making it faster and more accurate. They work by automatically storing and retrieving products, which reduces the time needed to locate items manually.

Businesses benefit from this technology as it enhances their ability to fulfill orders swiftly. This is crucial for maintaining customer satisfaction, building on the efforts to enhance customer experiences discussed earlier. Moreover, automated storage minimizes the chances of human error, ensuring that customers receive the correct items on time.

Energy Efficiency

Adopting energy-efficient systems is another stride towards operational excellence in fulfillment centers. These systems not only lower energy consumption but also reduce operational costs over time. They include LED lighting, efficient heating and cooling systems, and solar panels.

By reducing energy use, businesses can operate more sustainably. This commitment to sustainability can enhance a company’s image among environmentally conscious consumers. The savings from reduced energy bills can be reinvested into other areas of the business to further improve service quality.

Technological Advancements

Technological advancements have played a pivotal role in minimizing manual errors across the supply chain. With sophisticated software and control systems, fulfillment centers can better manage inventory and track orders in real-time. This visibility allows for immediate corrections if any discrepancies arise.

The impact of these technologies extends beyond individual centers; they enhance overall supply chain performance. Manufacturers and retailers can synchronize their operations more effectively, ensuring that products are available when and where they’re needed. This coordination is essential for meeting consumer demands promptly.

Sustainable Fulfillment Practices

Renewable Energy

Modern fulfillment centers are increasingly turning to renewable energy sources. This shift not only reduces their carbon footprint but also sets a new standard in the fulfillment process.

ar panels and wind turbines are now common sights on the roofs and grounds of these facilities. They harness natural resources to power operations, from lighting to automated sorting systems. The impact is significant, slashing electricity costs and decreasing reliance on fossil fuels.

Biodegradable Materials The use of biodegradable packing materials marks a pivotal change in how products are shipped. This initiative directly addresses the issue of waste reduction, a critical concern in the logistics sector.

Materials such as cornstarch peanuts and mushroom packaging replace traditional plastic and Styrofoam. These alternatives decompose naturally, leaving minimal environmental impact. Their adoption underscores a commitment to sustainability that resonates with eco-conscious consumers.

Energy-Efficient Systems Water usage is another area where fulfillment centers are achieving sustainability milestones. Through energy-efficient systems, these facilities significantly cut down on water consumption.

Low-flow fixtures and recycling programs ensure that every drop counts. Automated systems monitor usage, identifying leaks or inefficiencies promptly. This approach not only conserves water but also reduces operational costs, proving that sustainable practices can enhance profitability.

E-commerce and Modern Fulfillment

Growth Impact

The explosion of e-commerce has fundamentally altered how fulfillment centers operate. As online sales skyrocket, these hubs have evolved from simple storage spaces to complex, high-tech facilities. They now handle everything from inventory management to packing and shipping orders efficiently.

E-commerce companies rely heavily on fulfillment centers to meet customer expectations for fast delivery. This demand has led to innovations in order processing and supply chain management. Centers now use sophisticated software to track inventory in real-time, ensuring products are always ready to ship.

Flexible Services

Fulfillment centers have become more adaptable, offering flexible services tailored to the dynamic needs of online retailers. They can scale operations up or down based on seasonal sales fluctuations or promotional events. This flexibility is crucial for e-commerce businesses that experience varied demand throughout the year.

These centers also offer a range of shipping options, from standard freight to same-day delivery. By doing so, they help e-commerce companies remain competitive and responsive to customer preferences.

Strategic Design

The rise of e-commerce has influenced not only how fulfillment centers operate but where they’re located. Proximity to major transportation hubs is key for minimizing shipping times and costs. As a result, many new centers are strategically placed near airports, highways, and seaports.

Moreover, the design of these facilities reflects the need for efficiency and speed. They often feature advanced automation technology for sorting, packing, and storing goods. This allows them to process orders faster than ever before.

Future of Fulfillment Technologies

AI Automation

The integration of artificial intelligence (AI) and machine learning is set to revolutionize fulfillment centers. These technologies can predict order trends, optimizing stock levels and reducing waste. They streamline the picking and packing process, making it faster and more accurate.

AI systems learn from every transaction. This continuous improvement means they can adapt to changes in order volume or customer preferences quickly. Such flexibility ensures that fulfillment centers remain efficient, even during peak shopping seasons.

Blockchain Security

Blockchain technology offers unmatched transparency and security in supply chains. It creates a permanent record of every transaction that is nearly impossible to alter. This level of security builds trust among all parties involved in the fulfillment process.

By using blockchain, companies can easily trace the origin of products. This capability is crucial for quality control and for verifying the authenticity of items. Consumers value this transparency, as it assures them of the product’s quality and ethical sourcing.

Drone Delivery

Drone delivery represents a significant shift in how products reach consumers. It promises rapid delivery times, especially for last-mile deliveries. Drones can navigate to remote areas where traditional vehicles might struggle. This accessibility could open up new markets for e-commerce businesses.

However, drone delivery faces regulatory hurdles and safety concerns. As these issues get resolved, drones could become a common sight, zipping across our skies with packages.

Autonomous Vehicles

Autonomous vehicles are another game-changer in logistics. They can operate around the clock without human intervention, potentially reducing delivery times significantly. Self-driving trucks could undertake long-haul journeys overnight, ensuring goods arrive at fulfillment centers early each day.

This technology also has implications for urban deliveries. Small autonomous delivery bots could navigate sidewalks to deliver packages directly to customers’ doors. Such innovations would reduce traffic congestion and lower carbon emissions from delivery vehicles.

Global vs Local Strategies

Global Reach

Global fulfillment strategies allow businesses to access new markets and cater to a broader audience. They leverage international distribution centers to streamline operations across continents. This approach can significantly enhance brand visibility worldwide and tap into emerging markets.

However, managing a global network comes with its challenges. It requires substantial investment in logistics, technology, and compliance with various international regulations. Companies must navigate customs, taxes, and import laws that differ by country. These complexities can increase operational costs and complicate supply chain management.

Local Service

Local fulfillment centers are crucial for providing quick delivery times and reducing shipping costs. By positioning products closer to the end consumer, businesses can offer faster shipping options without breaking the bank. This strategy is particularly effective in meeting the expectations of customers who prioritize speed and convenience.

Moreover, local centers allow companies to adapt their offerings based on regional preferences and demands. They can stock products more relevant to the local market, ensuring higher customer satisfaction rates. However, focusing solely on local strategies might limit a business’s ability to scale globally.

Balancing Act

To meet diverse customer expectations, businesses must find the right balance between global reach and localized service. This involves establishing a robust network of global distribution centers while also investing in local fulfillment solutions where demand is highest.

Technology plays a pivotal role in achieving this balance. Integrating advanced fulfillment technologies can help streamline operations, reduce errors, and improve efficiency across both global and local networks. Businesses should utilize data analytics to understand market trends and customer preferences better, allowing them to adjust their strategies accordingly.

Final Remarks

From key services to future technologies, your journey through the realms of fulfillment and distribution centers has been comprehensive. You’ve seen how these hubs are not just about storage but are pivotal in enhancing customer experiences, embracing technology, and driving sustainability. The comparison between global and local strategies has underscored their significance in the e-commerce boom and the relentless pursuit of efficiency. Your understanding now spans the spectrum of what makes these centers tick and how they’re shaping the future of retail and logistics.

Now’s the time to leverage this knowledge. Whether you’re a business looking to optimize your supply chain or a curious mind fascinated by the logistics world, dive deeper. Explore how these insights can transform your approach or spark innovation. The future of fulfillment is bright and brimming with possibilities—be part of it. Start by reassessing your strategies or engaging with a fulfillment center today.

Frequently Asked Questions

What services do fulfillment centers typically offer?

Fulfillment centers provide storage, packing, and shipping services for e-commerce businesses, ensuring efficient order processing and delivery.

How do distribution centers differ from fulfillment centers?

Distribution centers focus on storing and distributing products in bulk to retailers or other distribution points, while fulfillment centers cater to individual customer orders.

What are the benefits of using a fulfillment center for my business?

Using a fulfillment center can enhance your customer experience through faster shipping times, reduce overhead costs by outsourcing logistics, and allow you to focus on core business activities.

How does technology improve fulfillment center operations?

Technology streamlines processes in fulfillment centers by automating order processing, inventory management, and shipping tasks, leading to increased efficiency and accuracy.

Can sustainable practices be integrated into fulfillment operations?

Yes, many fulfillment centers now adopt sustainable practices such as using eco-friendly packaging materials and optimizing shipping routes to reduce carbon footprints.

What role does e-commerce play in modern fulfillment strategies?

E-commerce has transformed fulfillment by necessitating rapid shipping, real-time inventory tracking, and flexible return policies to meet online shoppers’ expectations.

How is the future of fulfillment technologies shaping up?

The future of fulfillment technologies includes the adoption of AI for predictive analytics, drones for delivery, and robotics for warehouse automation to further enhance efficiency and customer satisfaction.