Ever wondered how your online orders arrive so neatly packed and swiftly delivered? It’s all in the commerce fulfillment and delivery. The shipping process plays a crucial role, and the shipping costs are factored in too. The secret lies in a process known as warehouse picking and pack fulfillment, a method that integrates order picking, packaging, and batch picking. This integral part of warehouse management, known as order picking, ensures that your items are picked, packed, and shipped efficiently in fulfillment operations. This commerce fulfillment is a vital part of the order fulfillment process. Packaging is more than just stuffing products into a box; it’s a crucial part of the commerce fulfillment and shipping process. It involves meticulous planning, precise execution, and the use of appropriate packing materials to ensure safe delivery in the order fulfillment process. With this inventory management software, ecommerce businesses streamline their shipping and packing operations, enhancing the overall order fulfillment process in their fulfillment warehouses. Dive in to discover how picking and packing can transform your shipping and inventory management, turning your fulfillment operations from ordinary to extraordinary.

Analyzing Pick and Pack Warehouse Operations

Breaking Down the Process Flow

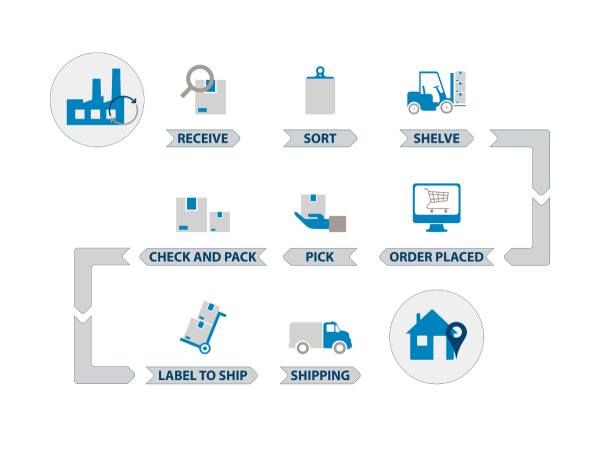

Let’s get down to brass tacks. A pick and pack system, vital in the order fulfillment process and inventory management, operates like a well-oiled machine. It starts with warehouse workers receiving an order. Then, they initiate the order fulfillment in ecommerce, fetching the goods from the warehouse shelves for the pack fulfillment process, hustling through aisles of inventory storage before shipping.

Here’s how it goes:

- The worker gets the order.

- They navigate to specific areas in the warehouse space.

- They pick items off the shelves.

- They pack it all up for shipping.

It’s not rocket science, but business and inventory management in ecommerce do require some serious organization skills and need!

Common Challenges Faced

Now, no system is perfect – packing and picking operations in order fulfillment and inventory management included. Sometimes, in the business of picking and packing for brands, you might encounter a few bumps on the road.

Here are some common issues:

- High ecommerce order volumes can cause mayhem if not managed properly through effective inventory management and fulfillment.

- In ecommerce, inventory levels could be inconsistent due to incorrect data entry or oversights in restocking, potentially affecting order fulfillment and the packing of orders.

- Warehouse workers might struggle with the order fulfillment process if inventory items are not sorted correctly, causing delays in picking and packing.

These business challenges can slow down fulfillment and inventory picking big time, but don’t sweat it! Every problem has a solution.

Key Metrics for Efficiency Evaluation

So how do we measure success? By keeping an eye on key metrics! These inventory numbers give us insights into how efficient our business operation, particularly fulfillment and ship processes, really is.

Let’s break it down:

- Order Accuracy: This fulfillment metric checks whether inventory orders are correctly picked and ready to ship.

- Fulfillment Order Cycle Time: This business measure calculates the inventory duration from when an order is received until it’s ready for pick pack shipment.

- Inventory Items Picked per Hour: This metric shows how many items each fulfillment warehouse worker picks and packs in an hour.

These inventory and picking metrics help us identify weak spots in our software so we can step up our fulfillment game!

Different Picking Methods

There are different software methods of inventory picking that can be used depending on your fulfillment needs like wave picking or zone picking, including pack processes. Wave picking in inventory management works best when dealing with high order volumes in fulfillment, while zone picking, often assisted by software, is ideal when you have to pack goods in a large warehouse space.

For example, wave picking, a fulfillment software feature, allows workers to manage inventory and pack multiple orders at once, which can save time. Zone picking, a key feature in inventory management software, assigns specific pack areas to each fulfillment worker, reducing travel time and increasing efficiency.

Ultimately, it’s all about picking the software that works best for your inventory fulfillment operation. So go ahead and experiment with picking, fulfillment, software, and inventory until you find your sweet spot!

Advantages of Pick and Pack Order Fulfillment

Cost-Effectiveness

Pick and pack fulfillment is a real money-saver. How, you ask? It’s all about reduced handling time. With pick and pack fulfillment, your individual orders are processed in one fell swoop by our inventory software, rather than being handled multiple times.

Imagine this: instead of manually picking up each inventory item from your order, packing it individually, and repeating the process for every single order, everything is coordinated at once using fulfillment software. It’s like preparing dinner for a big family – much quicker when you pick one large meal, pack it for everyone than making individual dishes! It’s a similar concept to inventory fulfillment.

This streamlined approach to fulfillment and inventory management, utilizing pick software, means less time spent on order handling (and we all know that time equals money!). Plus, less handling reduces the risk of damaging goods.

Enhancing Order Accuracy Rate

Nobody likes mistakes – especially not customers eagerly waiting for their orders to be picked, packed, and sent via efficient fulfillment software. That’s where pick and pack shines! It significantly boosts your order accuracy rate.

Think about it as playing darts. The more items you pick and pack, the higher the chances are that you’ll miss the target (or make an error), unless you use fulfillment software. By reducing the number of “shots”, pick and pack fulfillment software increases your chances of hitting bullseye with every single order.

Statistics back this up too! Businesses employing pick-and-pack services, supported by fulfillment software, have reported an increase in their accuracy rates by up to 99%. Now that’s something worth aiming for!

Improving Customer Satisfaction

Happy customers are repeat customers – it’s as simple as fulfillment, pick, pack. And nothing makes a customer happier than receiving their correct order, picked and packed with fulfillment, on time.

With its efficiency and accuracy, pick-and-pack fulfillment plays a crucial role in keeping those smiles coming. Fulfillment ensures faster delivery times because orders are processed more quickly through pick and pack methods. And remember our dart analogy? Fewer errors mean fewer disappointed customers.

And don’t just take my word for it! Numerous case studies highlight businesses experiencing improved customer satisfaction ratings and fulfillment after switching to a pick and pack system.

Implementing Pick and Pack Processes

Setting Up a Pick and Pack System

Setting up a pick, pack, and fulfillment system is like preparing for a big dance. You gotta have the right moves ready.

- First, you need to understand your inventory management process. It’s like knowing your dance floor.

- Next, create a fulfillment order picking list which will serve as your dance routine to pack.

- Then, decide on the fulfillment process, whether it’s batch picking, zonal picking, or piece picking – just like choosing your dance style. Don’t forget to pack everything securely.

Remember, each step is crucial in the pick fulfillment process.

Importance of Staff Training

Staff training is key to nailing that performance. Just as dancers need practice, so do your pickers.

- They must understand the complex picking and packing methods.

- They should know how to handle batch orders efficiently.

- Knowing how to use appropriate packing materials is also important for pick and fulfillment processes.

A well-trained staff can streamline the pick and fulfillment processes, ensuring smooth operation.

Role of Technology Integration

Technology integration in this fulfillment context is like having a DJ pick the music at your party. It sets the rhythm and keeps things flowing smoothly.

- A good inventory management software can automate the process to pick and fulfill orders.

- Barcode scanners speed up the fulfillment process by reducing errors in picking.

- Radio Frequency Identification (RFID) aids in picking and tracking products throughout the shipping process.

Incorporating technology makes the pick and pack process more efficient and accurate.

Role of 3PL Provider in Pick and Pack

Outsourcing to a third-party logistics (3PL) provider can streamline your pick and pack processes. Let’s pick apart the benefits of this arrangement and understand its cost implications.

Streamlining Pick & Pack with 3PL Providers

Imagine you’re running an online store. You’ve got orders rolling in left, right, and center. Now, you need to get these products out the door as fast as possible. This is where 3PL providers come into play.

- They use advanced warehouse management systems that automate the entire process.

- These systems ensure accurate picking and speedy packing.

- They also handle returns efficiently, saving you time and money.

For instance, Amazon uses Kiva robots in their warehouses for picking items. These robots have reduced human errors by a whopping 50%!

Benefits of Outsourcing to Experienced 3PL Providers

You might be thinking, “Why should I outsource when I can do it myself?” Well, here are a few reasons:

- Expertise: 3PL providers know the ins and outs of logistics like no other.

- Scalability: As your business grows, they can easily handle increased demand.

- Time-saving: No more worrying about managing inventory or dealing with shipping carriers.

Take Shopify’s Fulfillment Network as an example. It has helped over 10,000 businesses scale up without breaking a sweat.

Understanding the Cost Implications with 3PL Involvement

Now let’s talk about money matters. Yes, there are costs involved when outsourcing to a 3PL provider – but think about what you’re getting in return:

- Reduced overheads: You don’t need to maintain your own warehouse or hire staff for order fulfillment.

- Lower shipping rates: Thanks to their bulk buying power, many providers can offer discounted shipping rates.

However, keep in mind that not all 3PL providers are created equal. Some may charge hidden fees or lock you into long-term contracts. So always read the fine print!

In a survey by Inbound Logistics, 85% of businesses reported that partnering with a 3PL provider has led to overall cost savings.

Pick and Pack Software for Warehouse Management

The right warehouse management software can be a game-changer. It streamlines operations, offers real-time tracking, and comes in many varieties.

Essential Features of Warehouse Management Software

Warehouse management software is not just a fancy tool; it’s a necessity. It’s like your personal assistant that never sleeps.

- Automation: This feature reduces manual labor. Think of it as having an extra set of hands without the added cost.

- Scalability: As your business grows, so does the software. No need to worry about outgrowing your system.

- Integration: The software plays nice with others. It easily syncs with other systems you already use.

Real-Time Inventory Tracking

Imagine being able to know exactly what’s in your warehouse at any given moment. With inventory management software, this isn’t just wishful thinking – it’s reality.

- Accuracy: Say goodbye to human error. The system keeps track of every single item you have.

- Efficiency: No more wasting time searching for misplaced items. Everything is right where it should be.

Top-Rated Software Options

Choosing the right pick and pack software solution can feel like finding a needle in a haystack. But don’t sweat it – I’ve got you covered with some top-rated options.

- WMS Cloud by Oracle: This cloud-based solution is perfect for businesses looking to reduce their hardware footprint.

- Fishbowl Warehouse: A favorite among small businesses, Fishbowl offers robust features at an affordable price.

- Zoho Inventory: Known for its user-friendly interface, Zoho makes managing your warehouse a breeze.

Each one has its own unique strengths, so consider what matters most to you before making a choice.

Improving Efficiency with Automated Pick and Pack

Automation Reduces Human Errors

We all know humans aren’t perfect, right? We can make mistakes. ButThose errors can cost big bucks. That’s where automation steps in.

Automated pick and pack systems are like having a super-smart robot on your team. They’re designed to follow the most efficient route around your warehouse, grabbing the right products every time.

And guess what? These tech wonders don’t get tired or distracted. They work 24/7 without a coffee break! This means fewer mistakes and better quality control for your ecommerce business.

Cost Savings with Automation

Let’s talk about money, honey! Who doesn’t want to save some green? With automated pick and pack systems, you’ll see cost savings over time.

First off, these systems speed up order fulfillment. Faster work equals more orders out the door each day. You’re basically turning into an order-fulfilling machine!

Plus, good inventory management helps businesses cut down on wasted space and products collecting dust on shelves. It’s like spring cleaning for your warehouse!

Case Studies Show Improved Efficiency

Don’t just take my word for it though! There are plenty of case studies out there showing how automation improves efficiency.

Take Company X for example: they implemented an automated system and saw their error rate drop by a whopping 60%! Their customer satisfaction ratings also shot through the roof because orders were being shipped faster and more accurately.

Then there’s Company Y: after installing an automated system, they achieved 20% cost savings within a year due to reduced labor costs and increased productivity.

So yeah, folks – this stuff works!

Future of Pick and Pack Fulfillment

So, there you have it! We’ve taken a deep dive into the world of pick and pack fulfillment. From the nitty-gritty of warehouse operations to the benefits this system can bring to your business, it’s clear that pick and pack is a game-changer. With the help of 3PL providers and cutting-edge software, this process becomes even more efficient. And let’s not forget about automation – it’s like having a superpower that boosts efficiency sky-high!

The future of pick and pack fulfillment is bright, with continuous advancements paving the way for more streamlined operations. So why not jump on board? Give your business an edge over competitors by implementing these processes today. It’s time to take action!

FAQS

What is pick and pack fulfillment?

Pick and pack fulfillment is a process in warehouse management where items are picked from inventory based on customer orders and then packed for shipment.

How does pick and pack improve efficiency?

By reducing handling times and minimizing errors in order processing, pick and pack can significantly improve warehouse efficiency.

Why should I consider using a 3PL provider for my pick and pack needs?

A third-party logistics (3PL) provider has expertise in managing complex logistics operations such as pick-and-pack services. They can provide specialized knowledge, resources, technology, and infrastructure that may be difficult or costly for businesses to maintain on their own.

How does automation contribute to the effectiveness of pick-and-pack processes?

Automation reduces manual labor in picking items from inventory and packing them for shipment. This minimizes human error while increasing speed, accuracy, productivity, thus enhancing overall operational efficiency.

Can I implement Pick & Pack without any software?

While possible, operating without software could lead to inefficiencies due to manual tracking errors. A good warehouse management system helps streamline operations by automating most tasks involved in the Pick & Pack process.