Ever wondered how businesses keep their shelves stocked with inventory replenishment, manage orders without breaking a sweat through warehouse management, or store products in multiple warehouses? The secret lies in their choice between centralized and decentralized inventory models, involving multiple warehouses, warehouse management, economies, and store strategies. Each model, whether employing a centralized inventory or a decentralized inventory management strategy, offers distinct advantages and challenges in inventory replenishment, shaping the efficiency and flexibility of supply chain operations. In a world where customer satisfaction is paramount for company business operations, making an informed decision between these two models could mean the difference between thriving and just surviving for consumers and clients. This post dives into the heart of inventory management strategies, comparing centralized versus decentralized models to help you understand which might be the best fit for your business needs, focusing on the store merchandise and items through advanced planning. Let’s explore the key differences in production and find out how they impact everything from cost savings to delivery times, affecting items the company ships every day.

Key Takeaways

- Understand Your Business Needs: Before choosing between centralized and decentralized inventory models, assess your company’s unique requirements, including size, geographical spread, flexibility needs, production of items, and clients.

- Consider Centralization for Efficiency: If your business prioritizes efficiency, production, and cost savings, a centralized inventory model can streamline operations by consolidating stock items in a single location for clients.

- Embrace Decentralization for Responsiveness: Opt for a decentralized model if your focus is on customer service and quick response times, as it allows for inventory of items to be held closer to end-users and clients, enhancing production efficiency.

- Weigh Challenges Carefully: Both models come with their own set of challenges; centralized systems can create bottlenecks, while decentralized systems may suffer from inconsistencies in inventory management.

- Leverage Technology for Decentralized Control: Implementing advanced technology is key to managing a decentralized inventory of production items effectively, ensuring visibility and control across all locations for clients.

- Adaptation is Key: The choice between centralized and decentralized inventory models for production items is not static. Be prepared to reevaluate and adapt your strategy as your business and the market evolve.

Inventory Management Explained

Strategy Importance

Inventory management is key to business success. It involves monitoring centralized inventory stock levels and ensuring products are available when needed.

A solid inventory management strategy prevents excess inventory and reduces storage costs. Businesses can maintain optimal stock levels with centralized inventory, avoiding both surplus and shortages. This balance is crucial for operational efficiency.

Ordering Process

The ordering process is the first step in managing inventory. Companies must decide how much merchandise to order and when, considering their centralized inventory.

This involves predicting demand and considering lead times from centralized inventory suppliers. Effective ordering ensures a smooth production process and timely order fulfillment through centralized inventory management. It keeps the supply chain moving without delays.

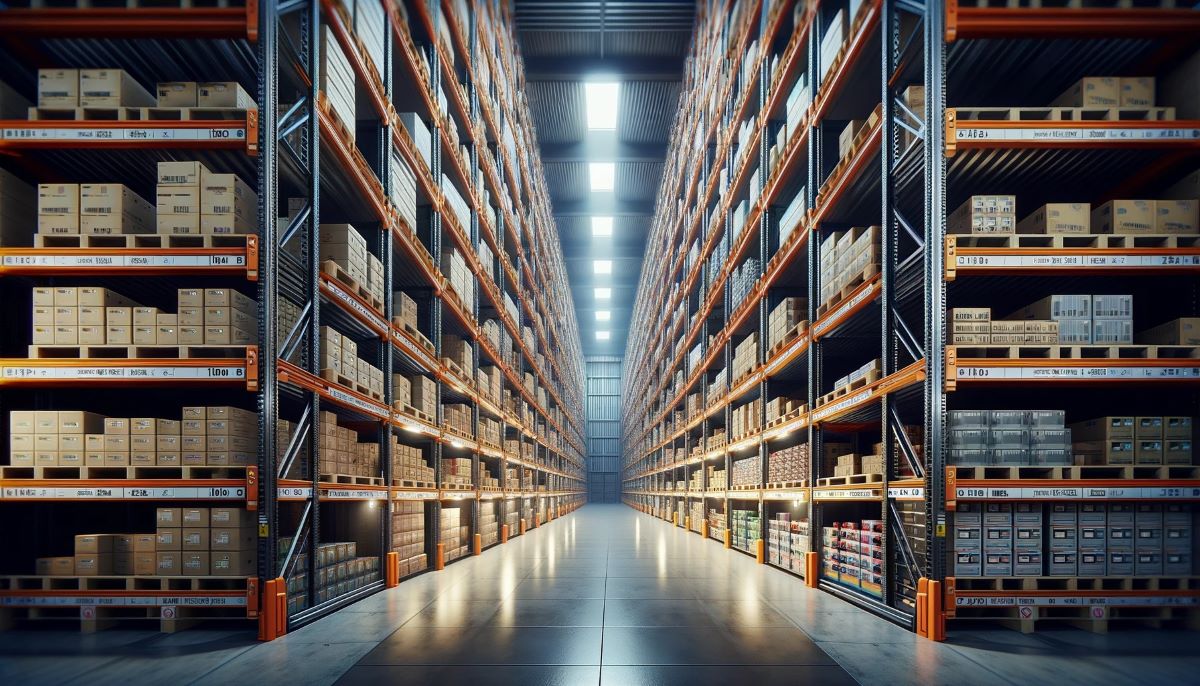

Storage Solutions

Once merchandise arrives, warehouse management becomes vital. Efficient storage solutions maximize storage space while keeping inventory accessible.

Proper organization of inventory locations allows for quicker retrieval of items for shipping or production. This boosts overall logistics performance.

Sales Cycle

Selling the merchandise is the final step. Here, inventory counts are critical for knowing what’s in stock.

Real-time tracking helps businesses respond quickly to sales trends, adjusting their inventory replenishment accordingly. This agility improves customer satisfaction by meeting demand promptly.

Supply Chain Efficiency

Inventory management plays a pivotal role in enhancing supply chain efficiency. By optimizing each stage – from ordering to selling – companies can ensure a smoother flow of goods through centralized inventory management.

This includes maintaining safety stock to handle unexpected surges in demand, minimizing distribution system bottlenecks, and utilizing centralized inventory. The result is faster order fulfillment and reduced operational costs due to centralized inventory.

Centralized Inventory Benefits

Simplified Control

Centralized inventory models streamline management processes. They make it easier to oversee centralized inventory stock levels and reorder supplies. This model allows businesses to maintain a clear overview of their inventory.

They can quickly identify which items in the centralized inventory are running low and need replenishment. This reduces the risk of stockouts and overstocking, ensuring that businesses can meet customer demand without holding excess inventory.

Reduced Costs

Centralizing inventory leads to significant cost savings. It cuts down on operational expenses associated with managing multiple storage facilities. Businesses can allocate resources more efficiently, focusing on optimizing one location instead of spreading efforts thinly across several.

This approach minimizes the costs related to logistics, such as transportation between different warehouses. It also reduces administrative expenses by centralizing inventory records and management systems.

Bulk Discounts

The centralized buying power of this model offers another key benefit: bulk purchasing discounts. By consolidating purchases, companies can negotiate better deals with suppliers. They buy larger quantities at lower prices.

This advantage not only lowers direct purchasing costs but also contributes to overall profitability. Businesses can pass savings onto customers or improve their margin.

Streamlined Logistics

Managing a single warehouse simplifies logistics and distribution significantly. It eliminates the complexities of coordinating shipments between multiple locations. Companies can focus on optimizing routes from one central point, enhancing efficiency in delivering products to customers.

This setup ensures faster shipping times and improves customer satisfaction. It also reduces the environmental impact by minimizing transportation needs, contributing to sustainability efforts.

Decentralized Inventory Advantages

Quicker Delivery

Decentralized inventory models boast faster delivery times. This is due to warehouses being closer to customers. It cuts down on wait times significantly.

Customers appreciate quick service. They are more likely to reorder when their needs are met swiftly.

Reduced Costs

This model also slashes shipping costs. Multiple locations mean shorter travel distances for products. This directly translates into savings.

Moreover, businesses can reach a wider audience. A broad consumer base is vital for growth.

Risk Mitigation

Decentralized inventories excel in emergency responses. They distribute products across various locations. This approach reduces the impact of natural disasters significantly.

Businesses can continue operations without major disruptions. This resilience is crucial for maintaining customer trust and loyalty.

Centralized Inventory Challenges

Single Failure

Centralized inventory systems often hinge on a singular location for storing goods. This setup poses a significant risk. A natural disaster or operational hiccup can halt the entire supply chain.

Businesses face the challenge of a single point of failure. They must ensure robust contingency plans are in place. Yet, even with precautions, recovery from such events is never immediate.

Shipping Costs

Another concern lies in the distance to customers. Centralized models may lead to higher transportation and shipping costs. Especially for those located far from the central warehouse.

Customers at greater distances experience longer wait times for their orders. This can lead to dissatisfaction and impact customer loyalty negatively.

Market Flexibility

Centralized inventories struggle with adapting to regional demands. They lack the agility needed to respond quickly to local market changes.

This limitation restricts businesses’ ability to offer region-specific products efficiently. It hampers their competitiveness in diverse markets.

Decentralized Inventory Challenges

Inventory Control

Managing a decentralized inventory involves complexities. Different warehouses mean varied stock levels to monitor.

Businesses often struggle with keeping an accurate count. This leads to either surplus or shortage. Surplus ties up valuable resources. Shortage disappoints customers. Both impact the bottom line.

Efficient control requires sophisticated systems. These systems track products across locations in real-time. Yet, they demand significant investment in technology and training.

Operational Costs

Decentralized inventories face higher operational costs. Each warehouse incurs expenses for staffing, utilities, and maintenance.

Coordinating shipments between these locations adds another layer of expense. It’s not just about moving goods from point A to B. It’s about doing so at the right time, in the most cost-effective way.

Businesses must balance these costs against the benefits of being closer to their customers. This is no easy task.

Technological Needs

A decentralized inventory system demands advanced technology. Without it, managing stock levels and coordinating shipments becomes nearly impossible.

Systems must provide real-time data on inventory across all locations. They must also integrate with suppliers and transportation services for seamless operations.

The challenge lies in both the initial setup and ongoing maintenance of these technologies. They require substantial investments in hardware, software, and cybersecurity measures.

Implementing Decentralized Control

Key Factors

Before diving into a decentralized inventory model, several factors need thorough consideration. Goods’ weight and delivery locations significantly impact the decision. Heavy items or those requiring specialized handling may benefit more from being stored closer to end-users. This reduces shipping costs and delivery times, enhancing customer satisfaction.

Running expenses also play a crucial role. Decentralization often leads to increased operational costs due to managing multiple storage facilities. Businesses must evaluate these expenses against the potential benefits of faster delivery and reduced transportation costs.

Order Volumes

Assessing monthly order volumes is essential in determining the need for additional warehouses. A spike in orders might indicate that your current setup is insufficient, pushing for decentralization. However, it’s important not to rush this decision.

Companies should analyze order trends over several months or even a year to make informed decisions. Seasonal fluctuations can misleadingly suggest the need for more storage space when, in fact, a temporary solution would suffice.

Technological Setup

A robust technological framework is indispensable for managing multiple warehouses effectively. Inventory tracking, real-time updates, and automated reordering systems ensure smooth operations across all locations. Without such technology, businesses risk losing track of stock levels, leading to overstocking or stockouts.

Integration with sales channels and transportation providers further streamifies the supply chain process. This connectivity allows for efficient order processing and dispatching from the most suitable warehouse based on stock availability and proximity to the customer.

Best Practices Decentralized System

Stock Balance

Balancing stock levels is crucial in a decentralized inventory model. It helps prevent overstocking or running into stockouts. Businesses should analyze historical sales data to understand demand patterns. This analysis allows for accurate forecasting.

They must adjust their inventory levels based on seasonality and market trends. Keeping a safety stock for unexpected spikes in demand ensures they never disappoint customers.

Product Monitoring

It’s essential to keep a close eye on bestsellers. These items drive the majority of revenue for many businesses. Companies should strategically store these products across various warehouses. This strategy reduces shipping times and costs.

Identifying slow-moving products is also important. They can be consolidated in specific locations to free up space for high-demand items. This approach optimizes warehouse space and improves overall efficiency.

Real-Time Data

Utilizing real-time data updates can significantly enhance decision-making in decentralized systems. It enables companies to respond swiftly to changes in demand or supply chain disruptions. Inventory management software plays a key role here.

Such software provides insights into stock levels, order status, and customer preferences across all locations. This information is vital for maintaining optimal inventory levels and ensuring customer satisfaction.

Centralized vs Decentralized Comparison

Shipping Expenses

Centralized models often lead to lower shipping costs. They store all goods in one location, cutting down on the expenses related to moving products between several locations. This model benefits organizations with a concentrated customer base.

Decentralized models, however, might increase shipping expenses due to goods being spread across multiple locations. Yet, they can offer faster delivery to customers far from the central warehouse.

Customer Satisfaction

In a centralized system, customers might face longer wait times for their orders. This is because all orders ship from a single location, regardless of the customer’s proximity.

Decentralized inventory systems shine in this aspect. They keep stock closer to diverse customer bases, enhancing order fulfillment speed. This quick turnaround boosts customer satisfaction significantly.

Delivery Times

Delivery efficiency varies greatly between these models. Centralized inventories can slow down delivery times as all products come from one place. For businesses serving a nationwide or global market, this can be a drawback.

On the other hand, decentralized systems ensure faster deliveries by leveraging multiple distribution points closer to end consumers. This model is ideal for organizations prioritizing speed and flexibility in meeting customer demands.

Business Nature Alignment

The nature of your business plays a crucial role in choosing the right model. Centralized inventory suits companies with stable demand patterns and less variety in products. It simplifies inventory management but may not cater well to rapid changes in consumer preferences.

Decentralized inventories are best for businesses facing fluctuating demands across different regions. They allow for more agile responses to market changes and customer needs but require sophisticated technology for coordination.

Technological Capabilities

Implementing a decentralized system demands advanced technological infrastructure. Organizations must invest in robust software to track and manage inventory across various locations effectively.

Centralized systems are less complex technologically but still benefit from modern inventory management solutions that enhance efficiency and accuracy.

Choosing the Right Model

Business Nature

Businesses must assess their nature and how it influences inventory management. A centralized model might suit companies with a uniform product line. They benefit from bulk purchasing and storing, reducing costs.

Decentralized models work well for businesses needing high flexibility to meet diverse customer demand. These companies often have multiple channels serving different segments of their customer base. Decentralization allows them to adapt quickly, offering tailored services.

Customer Base

Understanding your customers is crucial in selecting an inventory model. Companies with a broad, geographically dispersed customer base may find decentralized models more effective. This approach ensures products are closer to consumers, reducing transit times and enhancing customer service.

For businesses with a concentrated customer base, centralization can be a wise investment. It simplifies logistics and minimizes the risk of overstocking or stockouts.

Technological Readiness

The choice between centralized and decentralized also hinges on technological readiness. Advanced planning and analytics tools are essential for managing a decentralized system effectively. They help predict demand, optimize stock levels, and ensure timely delivery across all channels.

Centralized systems require less sophisticated technology but still benefit from tools that enhance inventory visibility and control.

Short vs Long-Term Objectives

It’s important to weigh short-term gains against long-term growth potential. Centralized models might offer immediate cost savings but could limit flexibility as the company expands. Conversely, decentralized systems may entail higher initial costs but provide the agility needed to capture new markets.

Businesses should align their inventory strategy with their overall growth plans, ensuring they can adapt as opportunities arise.

Consulting Experts

Making an informed decision requires expertise beyond internal capabilities for many businesses. Supply chain experts can offer valuable insights into how each model would work in practice, considering the company’s unique circumstances. They can also suggest ways to blend both models for optimal efficiency.

Consulting professionals can help identify potential pitfalls before they become costly problems, ensuring your inventory strategy supports your business goals.

Closing Thoughts

Choosing between centralized and decentralized inventory models is about matching your business needs with the right approach. Centralized systems offer simplicity and cost savings, while decentralized models shine in responsiveness and customer satisfaction. Each has its challenges, from managing complexity in decentralized systems to potential bottlenecks in centralized ones. Your choice impacts your supply chain’s efficiency, so weigh these factors carefully.

Now, it’s your turn to decide. Consider your business size, growth plans, and customer demands. Remember, the best inventory model is one that supports your operational goals and scales with you. Ready to optimize your inventory management? Start evaluating your options today for a leaner, more responsive supply chain.

Frequently Asked Questions

What is the main difference between centralized and decentralized inventory models?

Centralized inventory models consolidate stock in a single location, while decentralized models distribute inventory across multiple locations for closer proximity to customers.

How do centralized inventory systems benefit businesses?

Centralized systems reduce costs by consolidating storage and management, leading to improved purchasing power and streamlined operations.

What advantages do decentralized inventory models offer?

Decentralized models enhance customer service with faster delivery times and greater responsiveness to local market demands.

What challenges do businesses face with centralized inventory?

Centralized inventory can lead to higher transportation costs for distant customers and potential delays in order fulfillment.

Are there significant challenges associated with decentralized inventory systems?

Yes, decentralized systems can result in increased operational complexity and higher overall costs due to managing multiple storage locations.

Can you implement decentralized control easily in any business?

Implementing decentralized control requires careful planning, technology investment, and a shift in organizational mindset but is achievable with the right strategy.

How should a business choose between a centralized or decentralized model?

Consider your business’s scale, customer distribution, product types, and logistical capabilities. Opt for the model that aligns best with these factors for efficiency and customer satisfaction.